Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

Frame-type impurity removal machine(60~600mm)

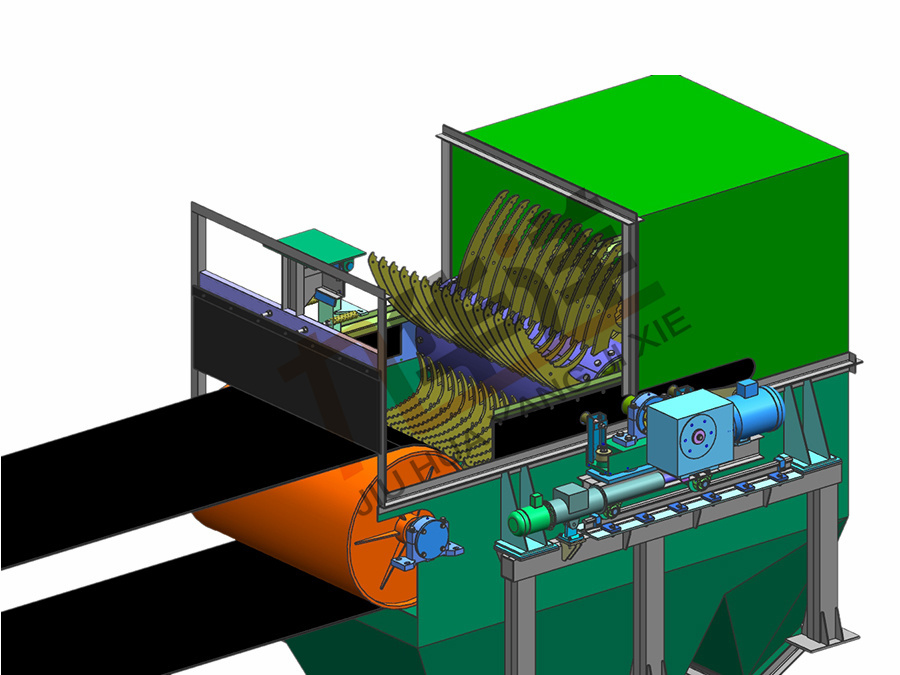

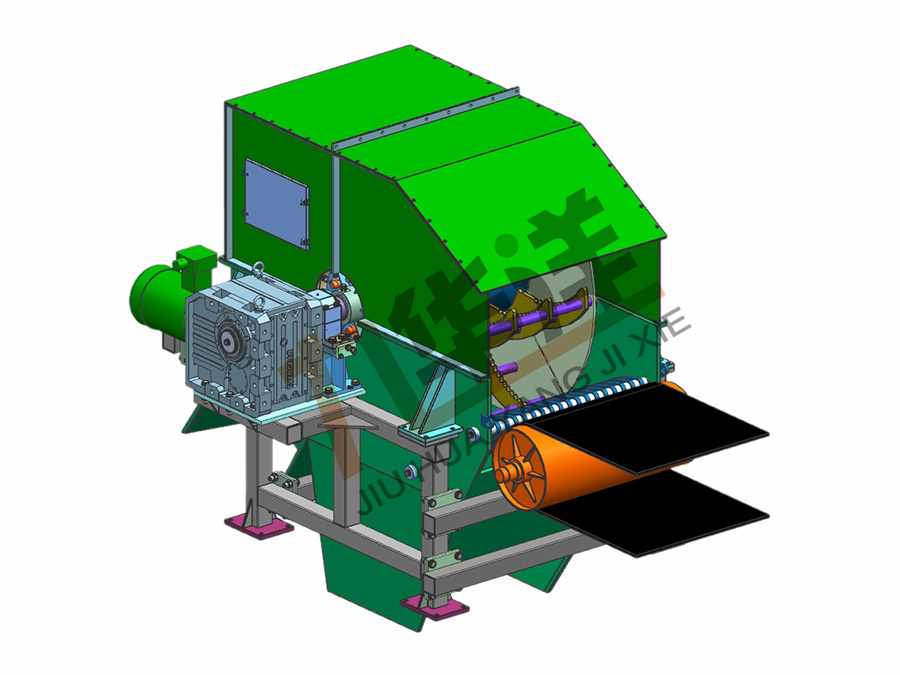

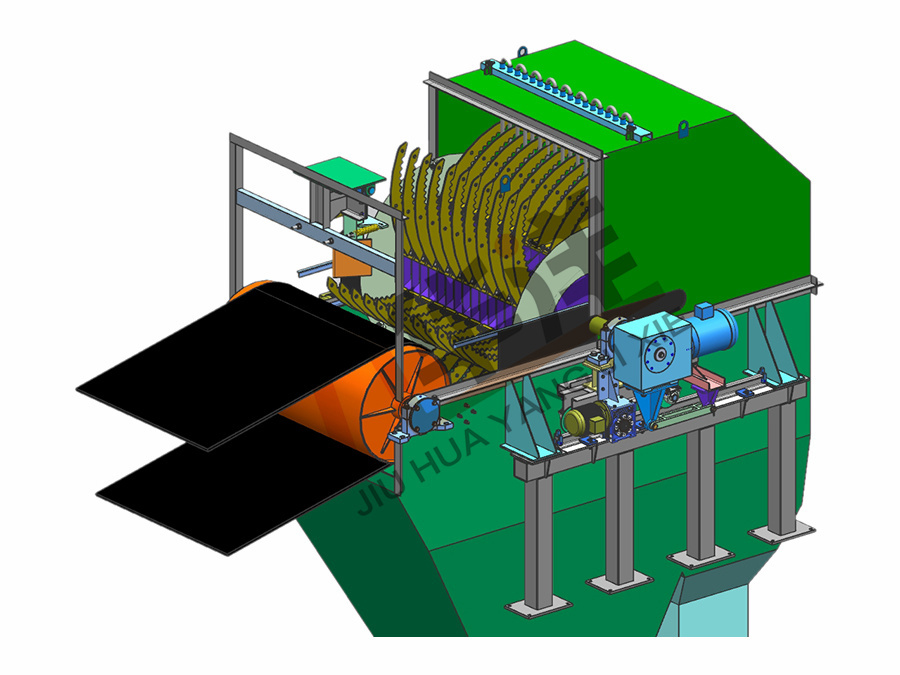

Working principle: Frame-type impurity removal machine is usually installed in front of the head roller of belt conveyor or under the blanking chute. After the incoming material passes through the elastic material diversion device, the coal flow is regulated into a flat shape; coal flows fall from the head of the belt conveyor, passing through the main rotor of the impurity discharging machine driven by the speed reduction motor, and entering the next level of equipment through the blanking pipe following screening; large pieces of waste rock, wooden sticks, straw mats, rags, hemp ropes, woven bags, support nets and other sundries in the coal flow are taken out by the tooth plate (among which, the mixed broken coal and finished coal enter the next level of equipment through the pores of the framework-type rotor), and when they rotate to the other side, they pass through the automatic impurity cleaning device and the impurity pipe, and finally fall into the ground sundries pool.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Structural composition

The impurity removal machine is driven by a motor and a speed reduction motor to rotate the tooth shaft where an adjustable tooth plate is installed. It mainly consists of elastic material regularization mechanism, adjustable screen tooth separation device, full floating frame work-type roller, torque arm floating connection speed reduction motor, elastic support, automatic impurity cleaning device, tooth plate and roller self-cleaning device, box body, blanking chute, rack, electrical control system, etc.

Typical application

◎ Thermal power plants without dry coal sheds carefully remove impurities, and remove smaller impurities from wet raw coal in rainy season;

◎ When the impurity removal machine in thermal power plant is added or reconstructed, the site building, space location and construction conditions are not conducive to impurity removal;

◎ It is suitable for coal conveying in coal preparation plant that needs to remove large blocks and impurities before materials enter the washing system;

◎ Impurities of coal washed with water in coking plant are carefully discharged. Due to human factors such as transportation and transshipment (wood, straw, woven bags, etc. are mixed into), the system is blocked, and coal blending and weighing are inaccurate, which seriously interferes with coal humidity control and coke particle size ratio;

◎ Impurities of coal washed with water in coking plant are carefully discharged. Due to human factors such as transportation and transshipment (wood, straw, woven bags, domestic garbage, etc. are mixed into), those impurities result in congestion of coal bunkers and separators;

◎ When the ore raw material preparation workshop carefully discharges impurities, mineral powder is easy to bond when humidity is high, and it is easy to stick under the influence of magnetism;

◎ It is suitable for vacuum mining and sorting of ore in water. The product can be installed on large mining ships to remove impurities such as aquatic plants, shells and pebbles.

Actual efficacy

◎ It is suitable for sticky and wet materials and application that requires careful impurity removal and high standards;

◎ Occupying a small space, it can run smoothly and remove impurities under harsh site conditions;

◎ The impurity removal efficiency can reach more than 95%, and the useful materials mingled in impurities are less than or equal to 0.5%.

Technical characteristics

◎ It is suitable for large wooden blocks, large stones, rags, straw, fiber fabrics, hemp ropes, etc., and has good self-cleaning ability for sticky and wet materials containing high moisture;

◎ With the tooth plate and roller self-cleaning device, even when treating sticky and wet materials, no sticking, blockage, stagnation and other phenomena will occur;

◎ The framework-type rotor has multi-filtration and recovery devices. While removing impurities, the useful materials can be fully recycled without any waste of materials.

◎ The equipment enables variable-frequency speed adjustment within a certain range, so as to adapt to differences in flow rate and material properties;

◎ Small land occupation and flexible layout: It can be used in thermal power plants, coking plants, coal preparation plants, coal chemical plants, ironmaking plants, beneficiation workshops, mining ships, etc.;

◎ The equipment has two-stage vibration isolation, low noise, long service life, low installation requirements and low requirements for building construction intensity grade;

◎ It can effectively reduce dust pollution and greatly abate PM2.5 emissions;

◎ It can start with load, equipped with variable-frequency speed control and overload protection;

◎ It can be controlled locally or remotely;

◎ The equipment has low total power and power consumption.

Common specification

|

Frame-type impurity removal machine model |

Conveyor belt width(mm) |

Rated output(t/h) |

Maximum output(t/h) |

|

JHYPZ0806 |

800 |

600 |

1000 |

|

JHYPZ1008 |

1000 |

800 |

1250 |

|

JHYPZ1212 |

1200 |

1200 |

1400 |

|

JHYPZ1415 |

1400 |

1500 |

2000 |

|

JHYPZ1624 |

1600 |

2400 |

2800 |

|

JHYPZ1835 |

1800 |

3500 |

4200 |

|

JHYPZ2045 |

2000 |

4500 |

6000 |

Frame-type impurity removal machine(60~600mm)

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO