Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

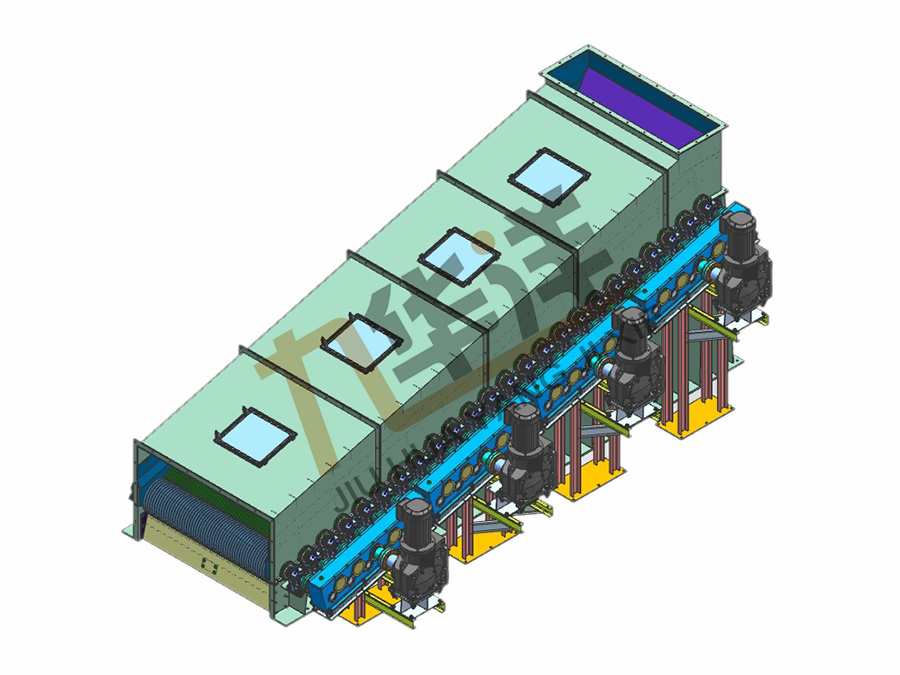

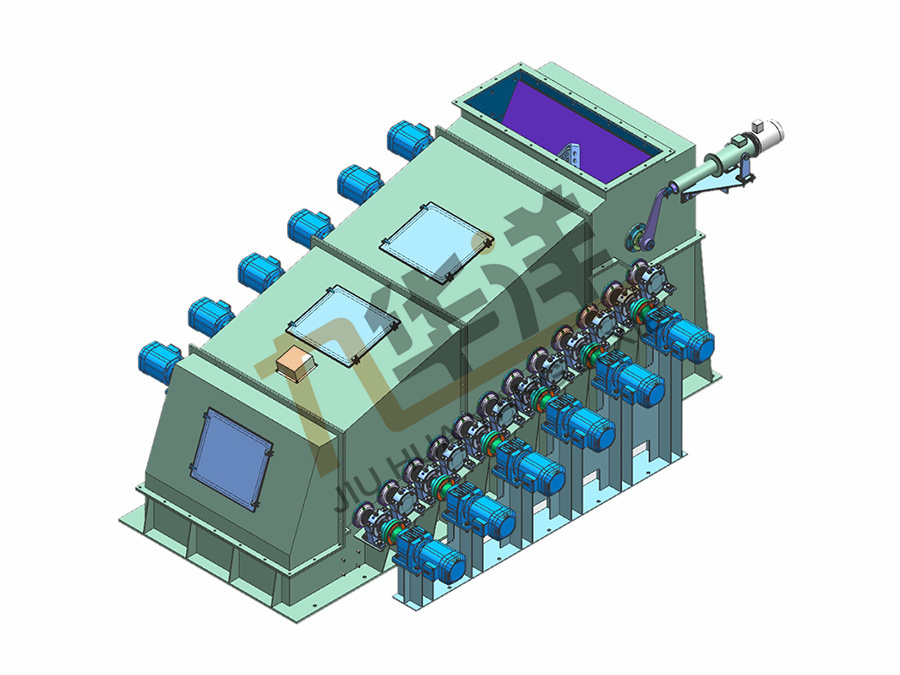

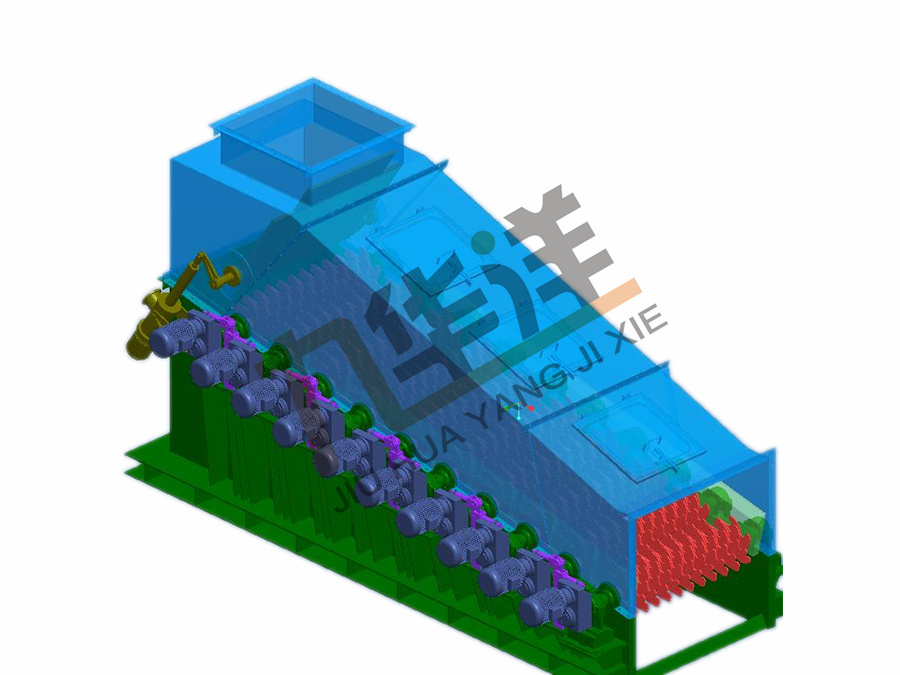

Floating blocking roller screen(20-300mm)

Working principle: The multi-axis rotation is used to push the material forward and screen at the same time. When the multi-axis rotation is in the same direction, the material larger than the sieve moves forward and enters the coal crusher. Material smaller than the sieve is passed through the sieve, through the hopper into the next level of belt. Use special combination sealing ring, good sealing, almost no dust overflow. The transmission mode is single shaft independent power source, and each screen shaft can float independently.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Working principle

The multi-axis rotation is used to push the material forward and screen at the same time. When the multi-axis rotation is in the same direction, the material larger than the sieve moves forward and enters the coal crusher. Material smaller than the sieve is passed through the sieve, through the hopper into the next level of belt. Use special combination sealing ring, good sealing, almost no dust overflow. The transmission mode is single shaft independent power source, and each screen shaft can float independently.

Material through the blanking pipe into the roller sieve, a number of sieve shaft rotation in the same direction, to promote the material along the screen to move forward, but also play the role of mixing materials. In the screening process, the material is distributed as far as possible in the direction of the width of the sieve shaft. After screening, the material less than or equal to the size of the screen falls through the screen, and the material larger than the screen (referred to as the material on the screen) continues to roll forward and eventually enters the coal crusher. At the same time, with a bypass device, materials can be directly into the next level of transfer belt. It can realize local manual control and remote centralized control.

Structural composition

It is composed of roller motor and coaxial reducer, floating device, screen shaft assembly, cleaning device, sealing device, frame, hood, bypass mechanism, coal blocking alarm and control system. When working, the screen shaft is driven by the motor of the roller table separately, and the multi-axis rotates in the same direction, and the material rolls forward, so that the material forms uniform and equal thickness layout on the screen surface. In the rolling process of the material, the material less than the sieve falls, the large material rolls over the screen surface and enters the coal crusher.

Technical characteristics

◎ Anti-stuck and anti-blocking spring element is arranged under the bearing seat of each screen shaft, which is independent floating type and can make limited displacement in a certain range.

◎ The shape of screen piece is hyperbolic and streamlined, good adaptability to viscous and wet materials, and can effectively prevent plugging.

◎ The screen is made of high strength wear-resistant steel with long service life. It can be replaced separately during maintenance.

◎ Screen technology adopts CNC laser cutting and forming, which does not change the mechanical properties of raw materials.

◎ Single shaft drive each screen shaft is driven by a separate deceleration motor. The failure of one screen shaft will not affect the work of other screens.

◎ Automatic cleaning Each screen shaft is equipped with a self-cleaning device, which can effectively scrape away the attachments and entanglements on the screen shaft and screen piece.

◎ Bypass function Built-in bypass function, you can switch freely.

◎ Material blocking alarm The material on the screen cannot be transferred in time due to special reasons, which leads to pipeline blocking, triggering the material blocking alarm signal.

Common specification

|

Floating blocking roller screen |

Screen width(mm) |

Number of sieve shafts |

Rated output(t/h) |

remarks |

|

JHYFDS0806 |

800 |

6 |

500-550 |

Affected by physical parameters such as material type, moisture content, viscosity, debris content, and particle size distribution range, technical parameters of equipment may change. |

|

JHYFDS1007 |

1000 |

7 |

800-850 |

|

|

JHYFDS1208 |

1200 |

8 |

1000-1100 |

|

|

JHYFDS1409 |

1400 |

9 |

1200-1300 |

|

|

JHYFDS1610 |

1600 |

10 |

1500-1600 |

|

|

JHYFDS1612 |

1600 |

12 |

1750-1850 |

|

|

JHYFDS1812 |

1800 |

12 |

2000-2100 |

|

|

JHYFDS2014 |

2000 |

14 |

2600-2700 |

|

|

JHYFDS2016 |

2000 |

16 |

3000-3200 |

Floating anti-blocking Roller screen (20-300mm)

Next page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO