Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

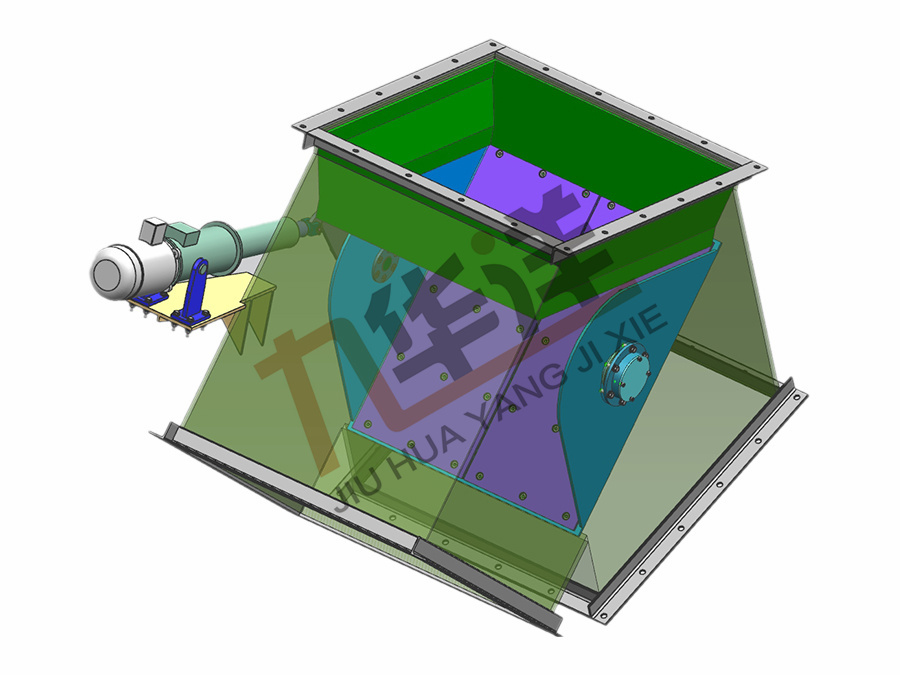

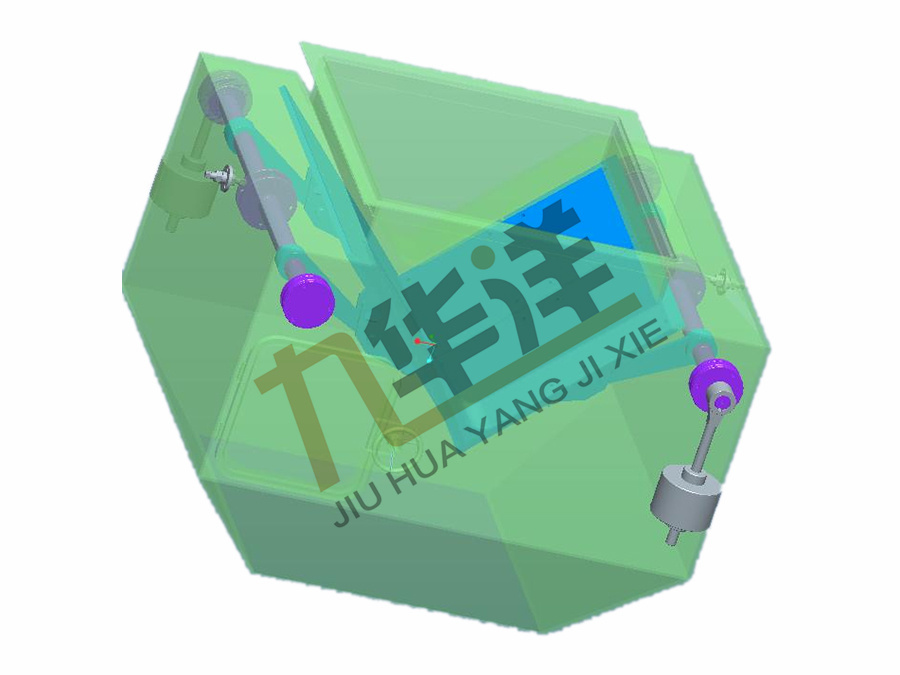

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

Cleaner

JHYQSQ-H self-adjusting type the first polymer cleaner is installed on the surface of the roller belt on the head roller and below the parabolic track of the material. The pre-shovel cleaning method is adopted, and the blades are made of polymer polyurethane modified material, which is resistant to wear, corrosion, fracture and hydrolysis, and does not damage the belt. The sweeper has a spring tension adjuster that automatically follows, compensates and ensures close contact between the blade and the belt when the blade is worn or the belt is jerked.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

JHYQSQ-H the first polymer cleaner

JHYQSQ-H self-adjusting type the first polymer cleaner is installed on the surface of the roller belt on the head roller and below the parabolic track of the material. The pre-shovel cleaning method is adopted, and the blades are made of polymer polyurethane modified material, which is resistant to wear, corrosion, fracture and hydrolysis, and does not damage the belt. The sweeper has a spring tension adjuster that automatically follows, compensates and ensures close contact between the blade and the belt when the blade is worn or the belt is jerked.

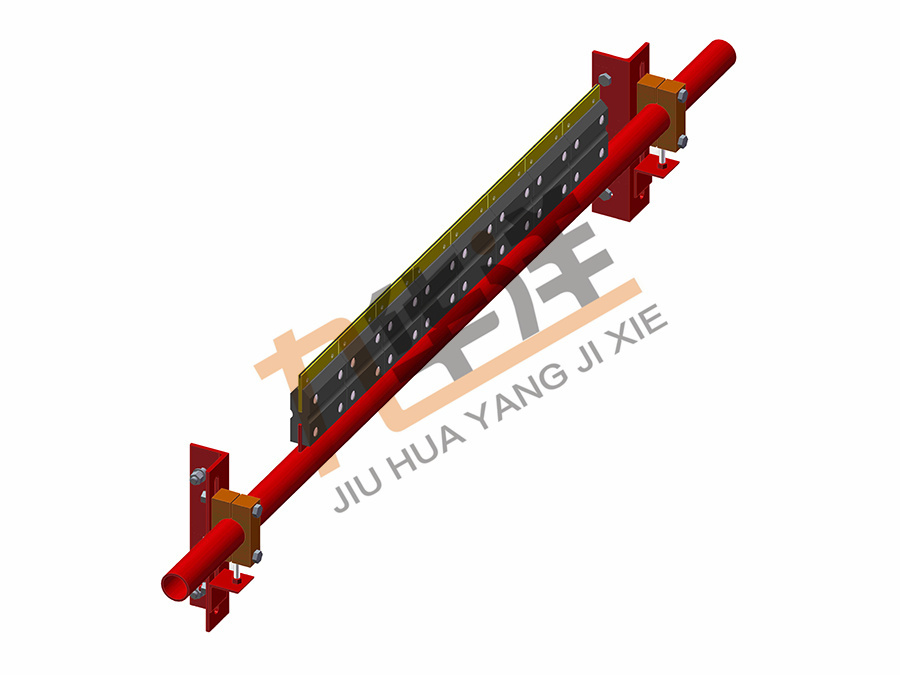

JHYQSQ-P second alloy blade cleaner

JHYQSQ-P self-adjusting second alloy blade cleaner is installed on the flat working face of the lower return belt of the head wheel. When used with the first cleaner, the pressure of the spring can automatically compensate the gap caused by the friction between the alloy blade and the belt conveyor, so as to keep the blade in close contact with the belt conveyor; The combined alloy blade can clean up the dirt in the depression, and easy to maintain and replace; Special blade Angle, remove belt adhesive effect is good, and does not damage the belt.

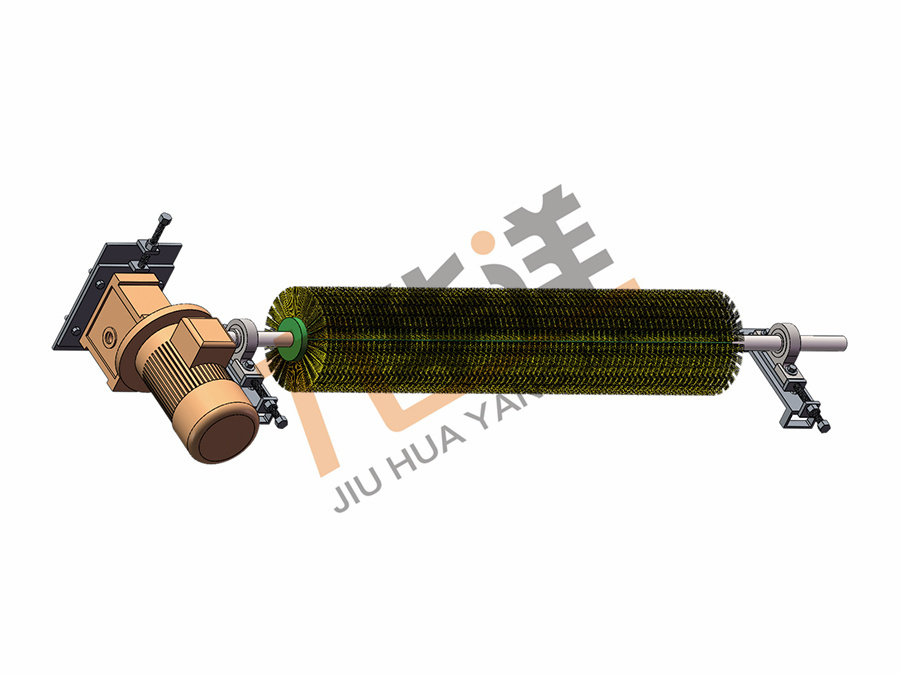

JHYQSQ-DS Electric Rolling Brush cleaner

JHYQSQ-DS electric brush cleaner, with easy replacement of wear-resistant nylon brush roller, brush wire is wear-resistant, elastic resistance, high temperature resistance nylon silk 1010 material. Elastic contact of cleaning point, no wear and tear to the conveyor belt, more no scratch, effectively extend the service life of the belt; The bristles can be made of high elastic nylon silk, also can be made of anti-static high elastic nylon silk, wear-resistant rubber and other excellent materials. Suitable for various belt conveyors.

JHYQSQ-WS Non-powered dry Brush cleaner

JHYQSQ-WS non-powered dry brush cleaner, relying on passive roller and belt friction to provide power, no power and control device. When the conveyor is running, the friction force is used to make the "drive roller" rotate with the conveyor, and the cleaning roller is driven by the drive box to rotate, and the movement direction is opposite to the return belt, so as to sweep the adhesive material on the return belt into the box.

JHYQSQ-X double helix cleaner for open working face

JHYQSQ-X air working face double screw cleaner, installed in the return belt under the flat working face, installed at intervals of a group, for cleaning the working face of the conveyor belt; It is beneficial to remove the material bonded on the belt working surface and improve the belt deviation caused by this phenomenon. Left and right double helix, easy to scrape and discharge; And simple structure, long life.

JHYQSQ-I/V high polymer cleaner for void non-working face

JHYQSQ-I/V self-adjusting polymer segment cleaner. If the belt conveyor is bidirectional reversible belt, the segment cleaner is "I" type; If the belt conveyor is unidirectional belt, the empty section cleaner is "V" type. Usually installed in the tail return belt above the flat non-working face, for cleaning the non-working face of the conveyor belt; It is good for the belt and tail wheel to work normally and improve the belt deviation caused by this phenomenon. The blade is made of polyurethane polymer sheet, low friction coefficient, anti-corrosion, anti-fracture and will not hurt the belt, and simple structure, easy to maintain.

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO