Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

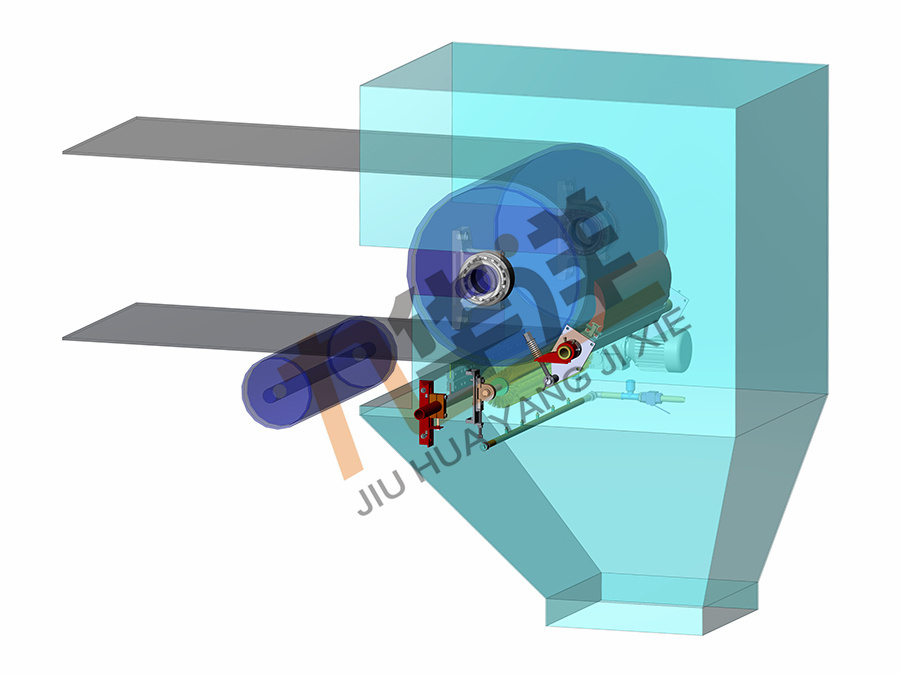

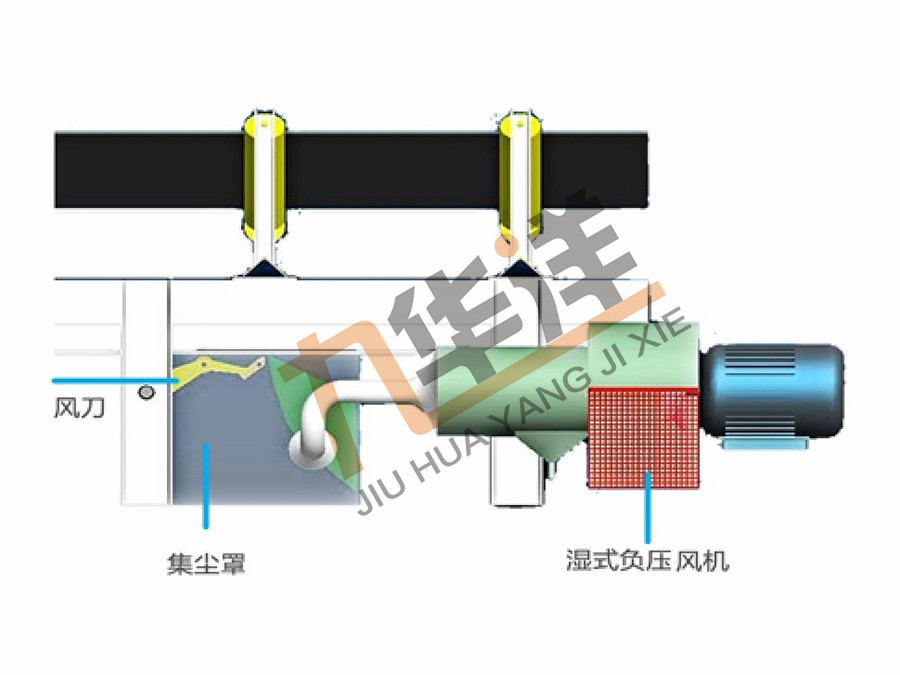

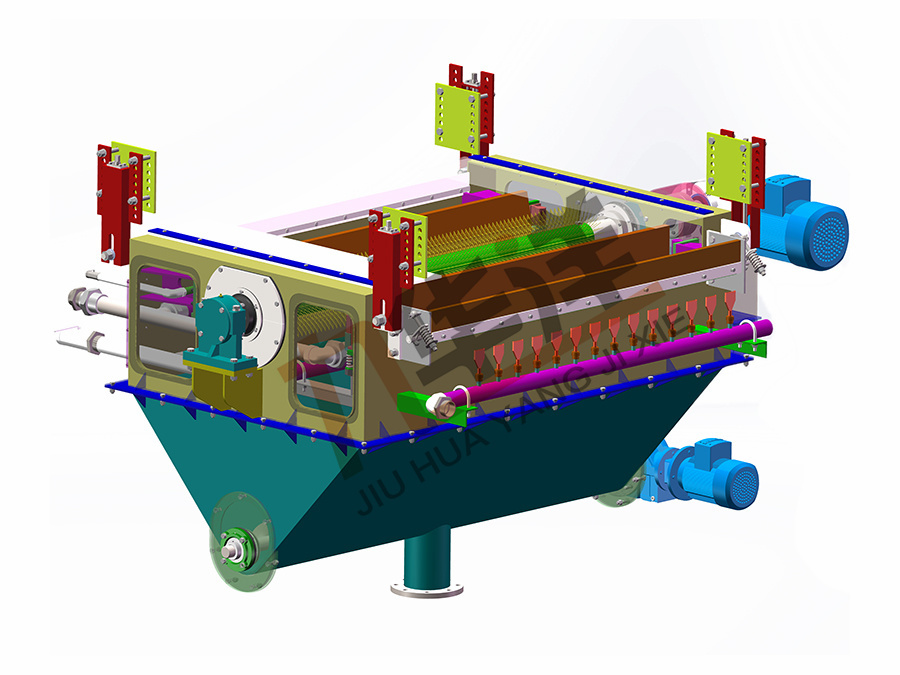

Tape washing, cleaning and air-drying device (wet type)

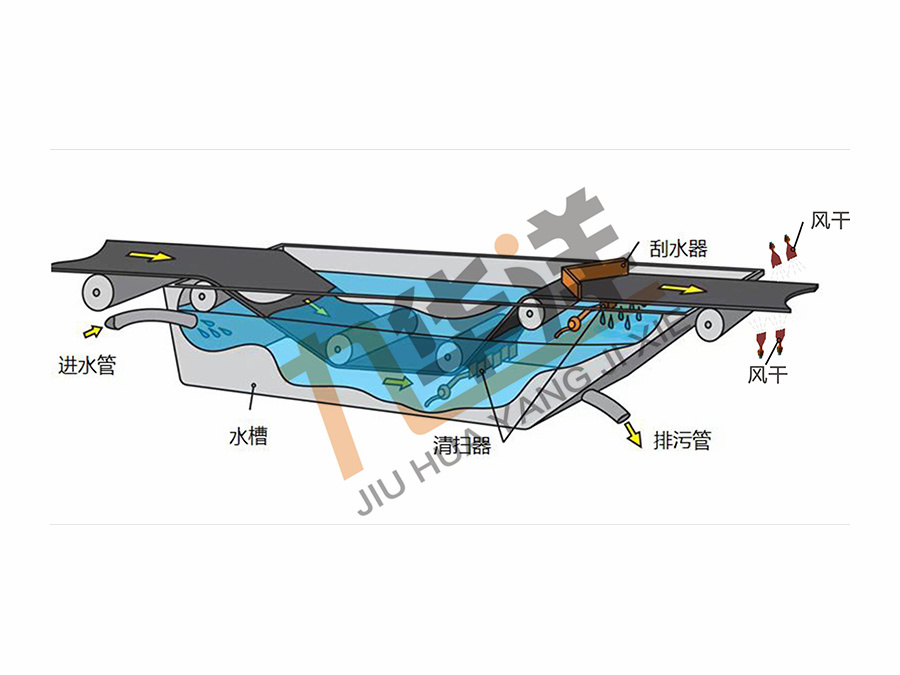

Working principle: The tape automatic cleaning device is a fully enclosed and sealed structure, mainly composed of a primary cleaner, a secondary cleaner, a wiper, a shell, a nozzle, a water tank, a pipeline, an air drying system, a control system, etc. The tape automatic cleaning device is installed on the lower working surface of the belt return section. During operation, a specially designed nozzle first softens the coal powder (coal slurry) adhering to the belt working surface. Under the scraping of the alloy cleaner, most of the coal slurry and water adhering to the belt working surface are removed, and then thoroughly removed through the polyurethane cleaner; Finally, it is blown dry through an air drying device. The cleaned sludge flows into the sewage pipeline under the action of impact water and is directed to the sewage treatment system in the factory.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Main characteristics

◎ Good cleaning effect: After cleaning, there is almost no coal slime residue.

◎ Good air-drying effect: Special air-drying design ensures that there is no water mark on the tape and prevents slipping.

◎ Automatic sewage discharge: The cleaned coal slime can be automatically discharged out of the box.

◎ Low water consumption: Compared with other tape water cleaning devices, the water consumption of our product can be reduced by about 20%.

◎ Automatic compensation of polyurethane cleaner: Automatic compensation function ensures that polyurethane cleaner and belt can be in good contact.

◎ Automatic operation or stop: It can automatically operate or stop according to needs (if necessary).

◎ Intelligent engineering: Mechatronics engineering and artificial intelligence design enable the belt conveyor to realize 24-hour unattended operation; and the running status can be monitored in the program control room.

Treatment method of cleaned sludge

◎ Impacted by water, the cleaned sludge flows into the sewage pipeline and is led to the sewage treatment system in the plant.

◎ Impacted by water, the cleaned sludge is led to the blanking pipe and enters the conveying system through the forward leaning pipeline.

◎ The cleaned sludge is led to the blanking hopper and enters the conveying system through the scraper conveying device below the cleaning device.

◎ The cleaned sludge is collected into the dewatering device where chemicals are added. After dewatering, the sludge falls to the material surface of belt and enters the production system along with the materials. The removed water flows back to the collection box for recycling.

Technical parameters

|

Specification and model |

Adaptive belt width(mm) |

Adaptive belt speed(m/s) |

Power(KW) |

Water source pressure(MPa) |

|

JHYSQX-500 |

500 |

≤5 |

≤2.2 |

≥0.3 |

|

JHYSQX-650 |

650 |

≤5 |

≤2.2 |

≥0.3 |

|

JHYSQX-800 |

800 |

≤5 |

≤2.2 |

≥0.3 |

|

JHYSQX-1000 |

1000 |

≤5 |

≤3 |

≥0.4 |

|

JHYSQX-1200 |

1200 |

≤5 |

≤3 |

≥0.4 |

|

JHYSQX-1400 |

1400 |

≤5 |

≤4 |

≥0.5 |

|

JHYSQX-1600 |

1600 |

≤5 |

≤4 |

≥0.5 |

|

JHYSQX-1800 |

1800 |

≤5 |

≤5 |

≥0.5 |

|

JHYSQX-2000 |

2000 |

≤5 |

≤5 |

≥0.5 |

|

JHYSQX-2200 |

2200 |

≤5 |

≤5 |

≥0.5 |

Tape washing, cleaning and air-drying device

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO