Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

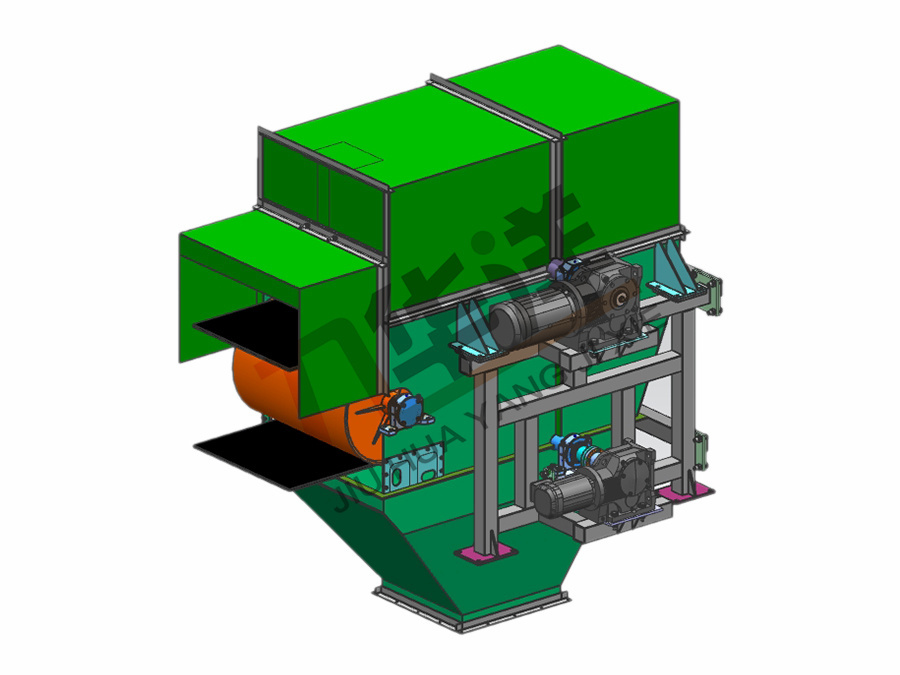

Double-toothed roller classifier crusher

Scope of application: forced classification double-tooth roll crusher is suitable for crushing hard, medium hard and soft materials with compressive strength less than 300Mpa. Can be widely used in mining, thermal power, cement, ceramics, metallurgy, chemical, building materials and other industries, the machine has the use of low maintenance cost, reliable performance, less dust, low noise characteristics.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Basic principle

Forced classification double-tooth crusher is the use of two wear-resistant alloy tooth rollers, relative rotation of high extrusion pressure to break materials, materials into the two teeth of the roller gap (V-shaped crushing chamber), by the two teeth of the roller relative rotation extrusion pressure and shear force, under the extrusion, shear and grinding, the material into the required size, and then sent out by the conveyor equipment. The relative rotation of the two rollers is like a sieve, only crushing materials exceeding the standard, and the products that have met the standards are directly broken through the crusher without secondary crushing. Only the exceeding material is broken, so as to save power and power requirements.

Scope of application

Forced classification double-toothed roll crusher is suitable for crushing hard, medium hard and soft materials with compressive strength less than 300Mpa. Can be widely used in mining, thermal power, cement, ceramics, metallurgy, chemical, building materials and other industries, the machine has the use of low maintenance cost, reliable performance, less dust, low noise characteristics.

Performance characteristics

◎ It has double functions of screening and crushing, and can complete screening and crushing operation independently.

The crushing tooth adopts spiral arrangement, and the relative rotation of two rollers is like a sieve, which can screen the materials smaller than the product size, and only the materials larger than the product size requirements are broken, avoiding the defects of coarse and fine materials mixed with crushing, and the product has high block rate, low over crushing rate and low crushing energy consumption.

The double-toothed roller is generally driven by "motor + hard-toothed surface reducer", which has simple structure, stable operation, small vibration, low noise and less dust.

◎ The structure size of the tooth roller is optimized according to the particle size of the product, the material is forced to break, and the space geometry size of the material is strictly controlled.

◎ Crushing tooth adopts high strength alloy, surfacing welded super hard wear-resistant material, durable, easy to maintain.

◎ The tooth roller is made of special steel pipe, and the surface is hardened by high-frequency induction heating.

◎ The eccentric bearing cup can adjust the roll distance, and the product size can be adjusted conveniently according to the demand.

◎ The equipment is equipped with self-cleaning mechanism, which can adapt to the crushing operation of wet and viscous materials.

◎ Equipped with overload protection device, to ensure the safe and reliable operation of the equipment and the whole system.

Structural characteristics

Groove hub The groove hub made of high strength cast alloy steel provides long-term stability for the tooth roll in harsh crushing applications.

◎ The combined shell design is convenient for fast and convenient maintenance gear roller to accurately control the discharge size of the product, while the dust and over-size products are very few.

◎ Toothed roller designed for maximum output - The core component of the crusher Roller crusher has excellent performance in crushing wet, dry, hot, cold, sticky, hard and abrading all kinds of materials.

◎ New material crushing teeth, high strength, wear-resistant, large processing capacity, high reliability, low noise, less dust. Disposable life is not less than 15000h, after grinding can be surfacing or replacement.

◎ There is no grate bottom, no requirement on material moisture content, no problem of blocking sieve plate, and no problem of fine powder can not be discharged in time and repeated crushing.

◎ The closed gear box makes the two toothed rollers reach complete meshing.

◎ Viscous wet material is non-stick, non-clogging, self-cleaning.

◎ Centralized lubrication system can provide semi-automatic or automatic lubrication system.

◎ Hydraulic coupler, flexible transmission, self-adaptation, shock mitigation, vibration isolation, light load starting, overload protection.

◎ Hard gear reducer, after reducing the speed of the gear roll, the torque is greatly increased, the formation of strong crushing, especially for hard materials such as stones.

◎ body integral welding, aging annealing, impact resistance, compact structure.

◎ Electric control system PLC sequence control, can adapt to harsh environment. The general use of explosion-proof motor, moving parts of multiple safety protection. The control cabinet is made of double-layer stainless steel shell, fully sealed structure, waterproof and dust-proof.

Materials that can be broken

◎ Coal from raw coal to cleaned coal, brown coal, bituminous coal, subbituminous coal, anthracite and frozen coal.

◎ Coal gangue and coal seam symbiosis, associated roof and surrounding rock, washing gangue picked out in the process of coal preparation, etc.

◎ Petroleum coke, metallurgical coke, raw petroleum coke and baking.

◎ Broken glass or glass bottles, plate glass, overflow glass on the production line.

◎ Fertilizer and potassium fertilizer MAP, DAP, potassium ore and potassium tablets, etc.

◎ Salt, sea salt, potassium chloride, sodium chloride.

◎ Quick Lime and limestone Soft to moderate hardness of limestone and dolomite as adsorbents for boilers, quick lime, hydrated lime.

◎ Soft ore shale, clay, phosphate, oil shale.

◎ Brittle material bottom ash, boiler slag, nuts and nut shells, cement slag, ceramic tile.

◎ Ore: borax, borax, nitrate, phosphate, talc.

◎ Hard to handle materials such as graphite electrode, thermal materials, viscous materials.

Common specification

|

Application type |

Feed size(mm) |

Discharge size(mm) |

Rated output(t/h) |

Remarks |

|

Coarse crushing |

4000 |

300 |

600~4000 |

customizable |

|

Coarse crushing |

500 |

50 |

400~2000 |

customizable |

|

Coarse crushing |

300 |

8 |

100~1000 |

customizable |

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO