Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

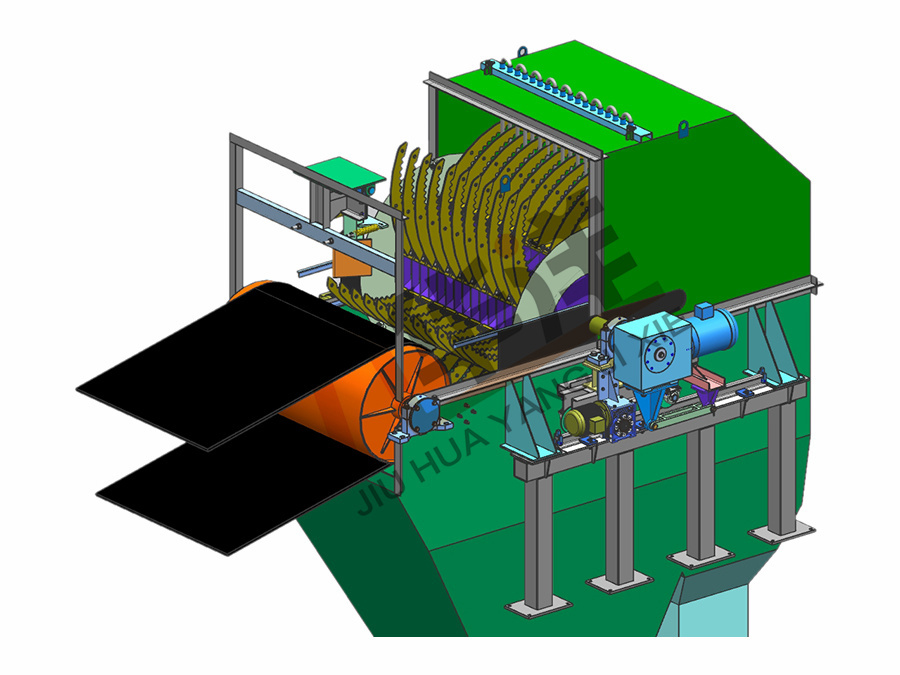

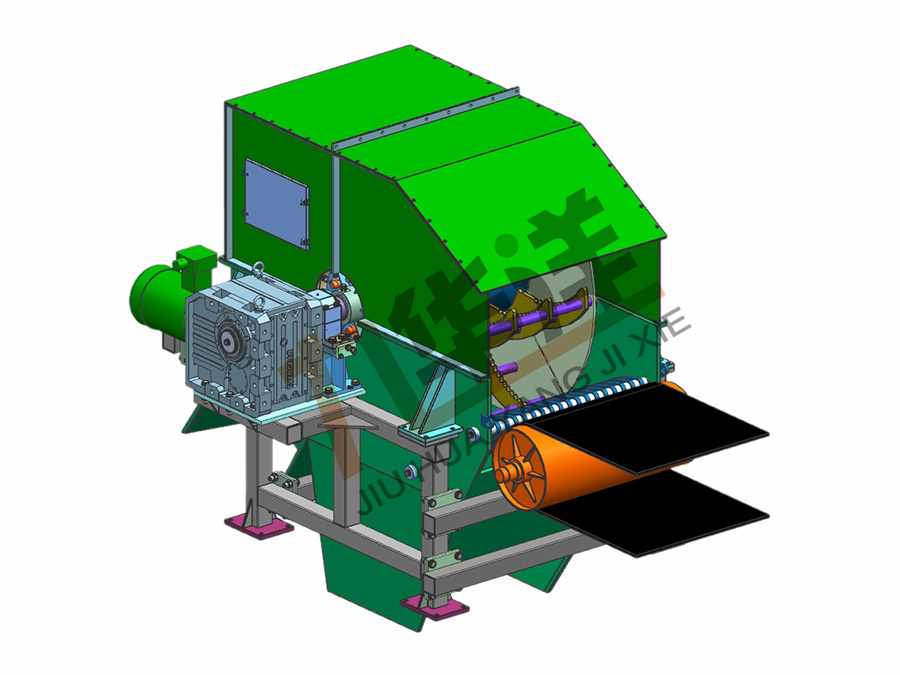

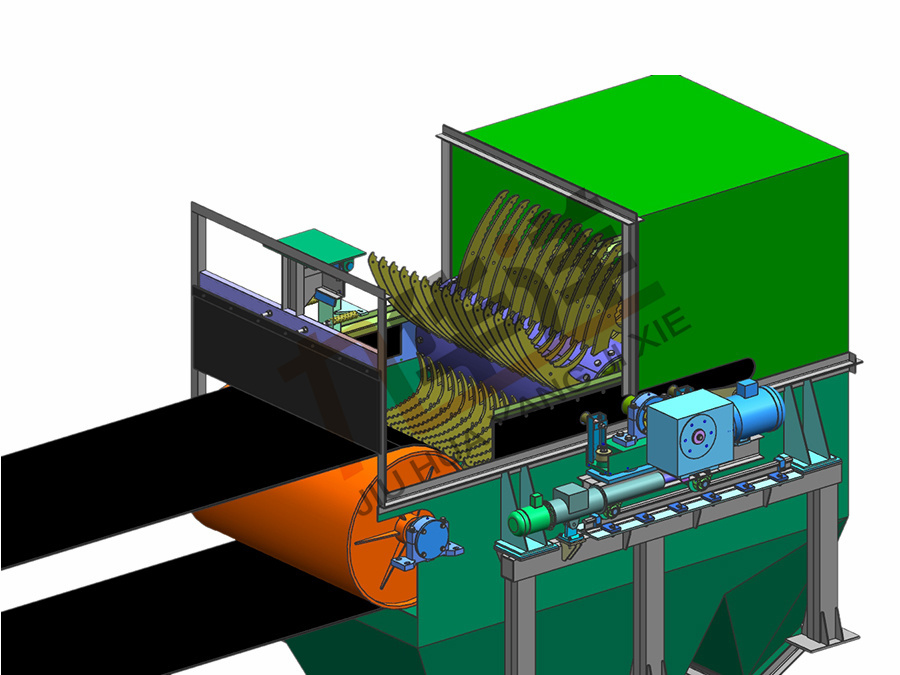

Frame-type block remover(80~800mm)

Working principle: Frame-type block remover is usually installed in front of the head roller of belt conveyor or below the blanking chute. After the incoming material passes through the elastic material diversion device, the coal flow is regulated into a flat shape; coal falls from the head of the belt conveyor, passing through the main rotor of the bulk removal machine driven by the speed reduction motor, and the broken coal passes through the blanking pipe and then enters the next level of equipment; large materials and impurities exceeding the standard in the coal flow are taken out by the tooth plate, and when they rotate to the other side, they fall to the multi-filtration and recycling mechanism under the action of gravity through the automatic impurities cleaning device. The mixed broken coal re-flows to the coal pipe through the return pipe, while large materials and impurities exceeding the standard pass through the impurities pipe and finally fall into the ground sundries pool.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Structural composition

This machine is mainly composed of shutter-type dust-proof curtain, elastic material regularization mechanism, wedge-shaped parabolic tooth plate, torque arm floating connection deceleration motor, full floating head roller, elastic supporting housing, automatic tracking and moving mechanism, multi-filtration and recovery mechanism, left and right upper box body, lower box body, support column and electric control system.

Application field

◎ Separation of solid bulk materials or solid-liquid interphase materials;

◎ It is suitable for separating large and small blocks between materials with different geometric sizes and removing impurities in the coal, coking, metallurgy, ore, building materials, chemical raw materials and other separation and pulverizing industries, ;

◎ It is suitable for pulverized coal equipment in thermal power plants to remove large blocks and large impurities exceeding the standard. It can also separate pulverized coal from lump coal, make pulverized coal pass, and make and lump coal enter the crusher after being separated. It is an ideal substitute for traditional screening equipment (idler screen, roller screen, hook tooth machine, big wood remover, big block removal machine, etc.).

Typical application

◎ Large blocks are removed before crushing coal for thermal power generation, and impurities are discharged before coal milling after crushing;

◎ Separation of large and small blocks and final coal in coal mine, and impurity removal;

◎ Separation of fine ore from lump ore in coal preparation plant and impurity removal;

◎ Material screening and impurity removal in the preparation of metallurgical, building materials and chemical raw materials;

◎ Separation and impurity removal in the process of port bulk material transportation.

Actual efficacy

◎ It is especially suitable for severe working conditions such as large flow rate, strong viscosity and complex components, without changing the original material properties;

◎ In the process of material conveying, it can effectively separate large blocks and impurities with arbitrary geometric shapes such as strips, blocks and fibers;

◎ The efficiency of removing large blocks or impurities is over 95%, and useful materials that do not exceed the standard are not involved;

◎ It can be used in series in multiple stages to further improve the separation and impurity removal efficiency.

Technical characteristics

◎ Flutter comb self-cleaning, unadjustable vibration frequency within a certain range;

◎ Spiral wedge-shaped parabolic tooth plate structure effectively increases the contact path and time between materials and tooth plate, without causing blockage;

◎ Optimal layout of special tooth plate can effectively separate large blocks and impurities with arbitrary geometric shapes such as strips, blocks and fibers;

◎ Tracking the actual working conditions such as speed, output and blanking point of conveyor belt, and automatically adjusting its position, speed, inclination and other parameters;

◎ The multi-filtration and recovery mechanism ensures that large materials and impurities exceeding the standard do not carry useful materials;

◎ The adjustable elastic material regularization mechanism can not only ensure the passage of large materials, but also make the materials contact with the tooth plate evenly;

◎ It can start with load, equipped with variable-frequency speed control and overload protection;

◎ It can be controlled locally or remotely;

◎ The equipment has low total power and power consumption.

Common specification

|

Model of frame type blocker |

Belt Width(mm) |

Rated Output(t/h) |

Maximum Output(t/h) |

|

JHYCK0806 |

800 |

600 |

1000 |

|

JHYCK1008 |

1000 |

800 |

1250 |

|

JHYCK1212 |

1200 |

1200 |

1400 |

|

JHYCK1415 |

1400 |

1500 |

2000 |

|

JHYCK1624 |

1600 |

2400 |

2800 |

|

JHYCK1835 |

1800 |

3500 |

4200 |

|

JHYCK2045 |

2000 |

4500 |

6000 |

框架式除块机

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO