Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

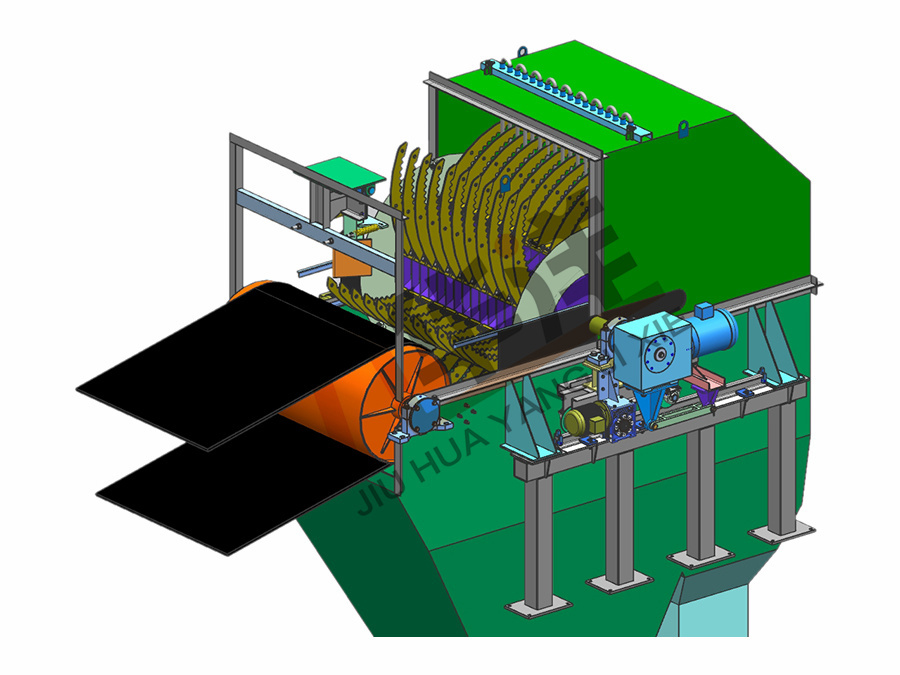

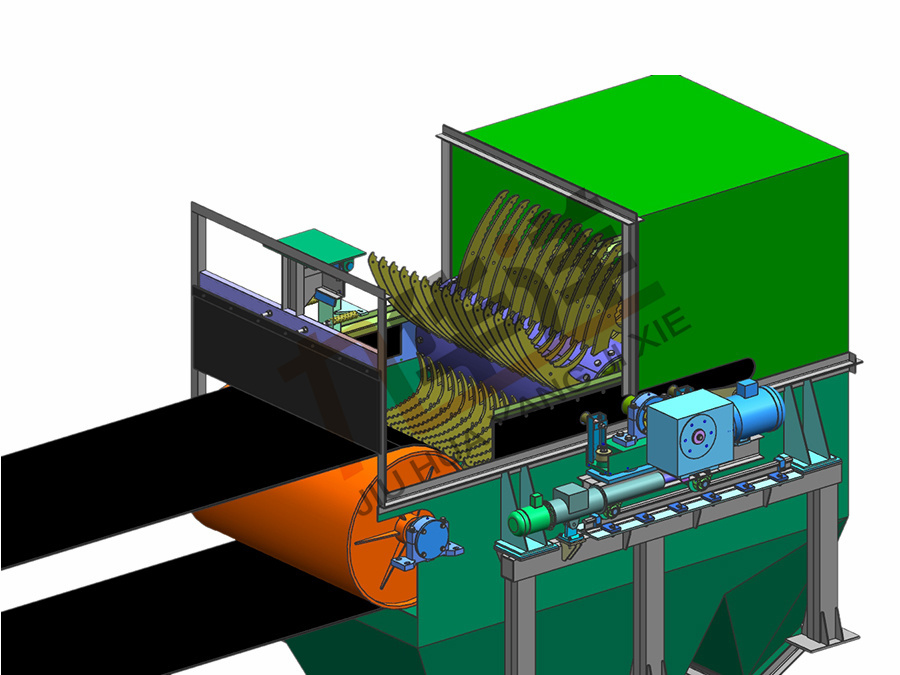

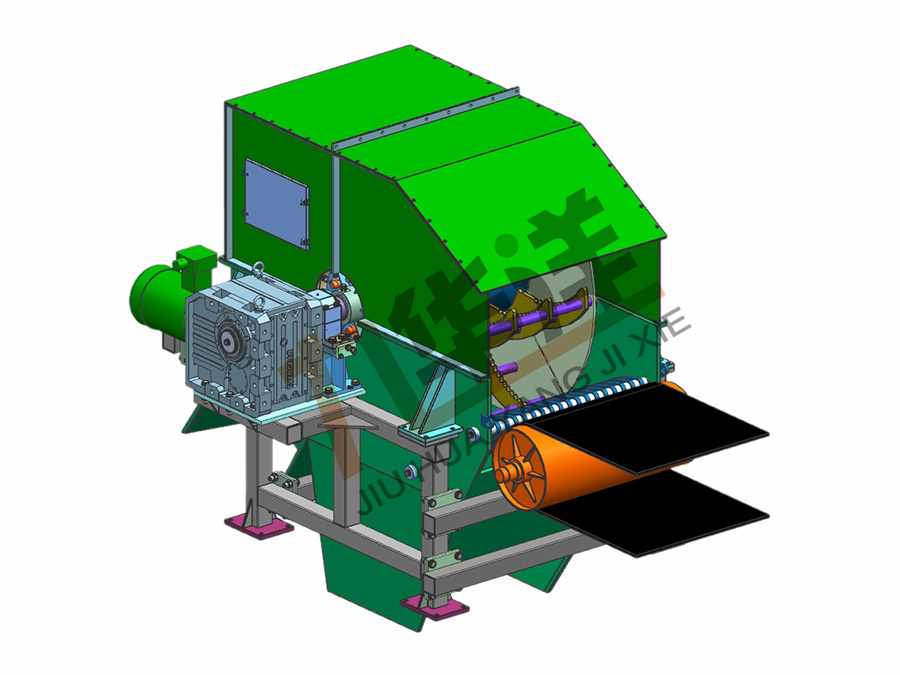

Powder discharge machine(10~60mm)

How it works: A sloping coal grate above the device blocks debris from passing through. Under the action of negative pressure, sundries are pushed upward along the bevel Angle of the coal grate. When sundries enter the top of the coal grate, they leave the effective area of the air flow, the adsorption force gradually decreases, and sundries fall into the upper chamber automatically, achieving the purpose of separating coal powder from sundries. When the sundries in the upper silo accumulate to a certain amount, flip board II will automatically open, sundries into the lower silo, when the sundries in the lower silo accumulate to a certain amount, open the artificial door to clear sundries. Small coal grates are set up in the upper and lower bins respectively to filter the remaining pulverized coal in the sundries and then return to the powder delivery system.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Application field

It is installed at the exit of pulverizer in pulverizing system for removing debris in pulverized coal.

Working principle

A sloping coal grate is placed above the device to block the passage of debris. Under the action of negative pressure, sundries are pushed upward along the bevel Angle of the coal grate. When sundries enter the top of the coal grate, they leave the effective area of the air flow, the adsorption force gradually decreases, and sundries fall into the upper chamber automatically, achieving the purpose of separating coal powder from sundries.

When the sundries in the upper silo accumulate to a certain amount, flip board II will automatically open, sundries into the lower silo, when the sundries in the lower silo accumulate to a certain amount, open the artificial door to clear sundries. Small coal grates are set up in the upper and lower bins respectively to filter the remaining pulverized coal in the sundries and then return to the powder delivery system.

Performance characteristics

◎ There is no need to turn the coal grate when the sundry machine is running, and no debris remains on the coal grate;

◎ There is a self-locking device between the two sundries, so there is no need to stop when cleaning sundries;

◎ Adopt multi-channel sealing device, completely sealed, no leakage of powder, no leakage of air, no loss of coal mill pressure.

Next page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO