Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

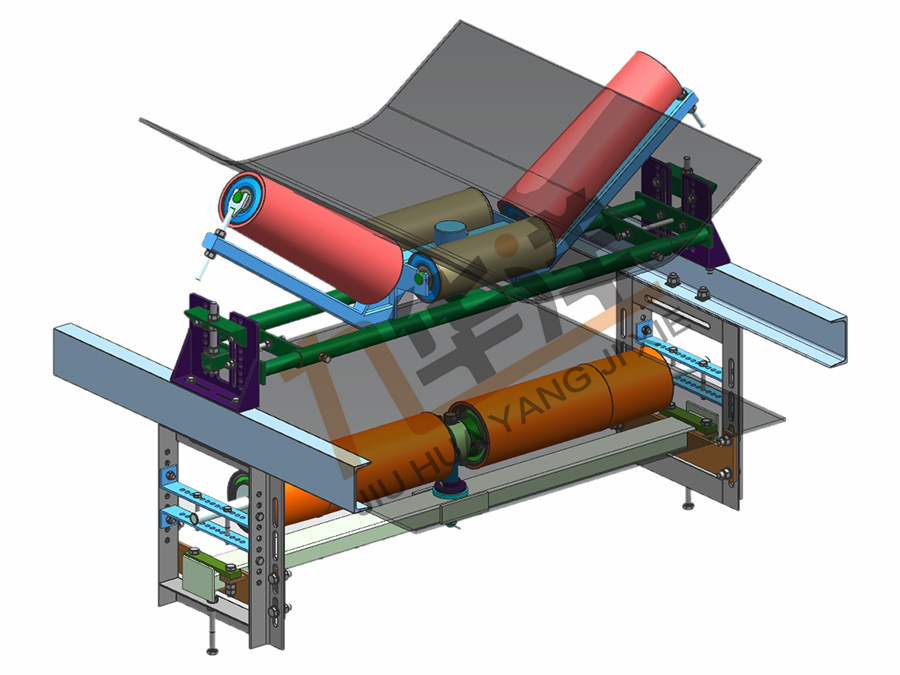

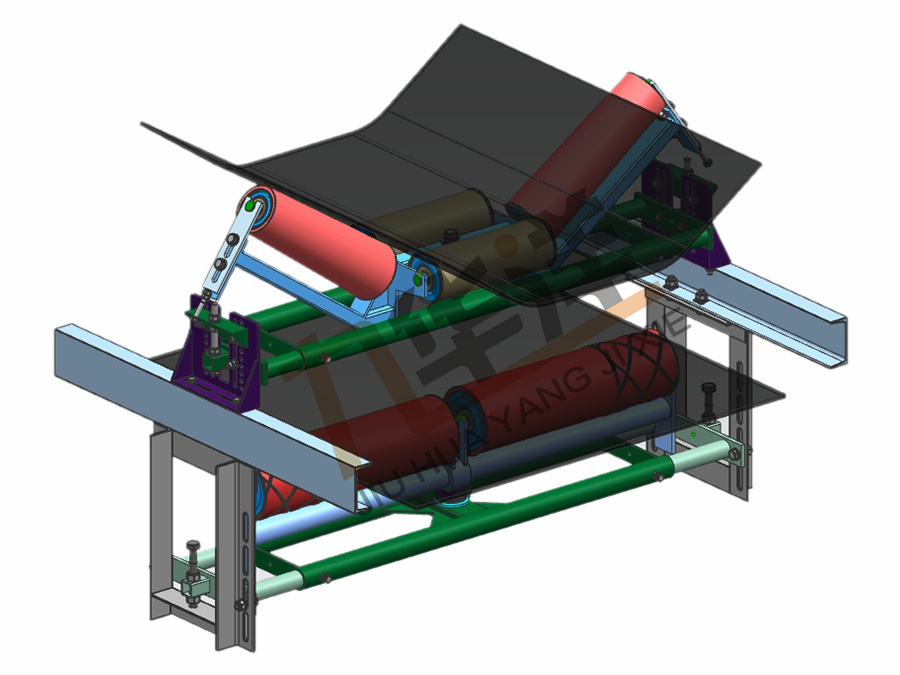

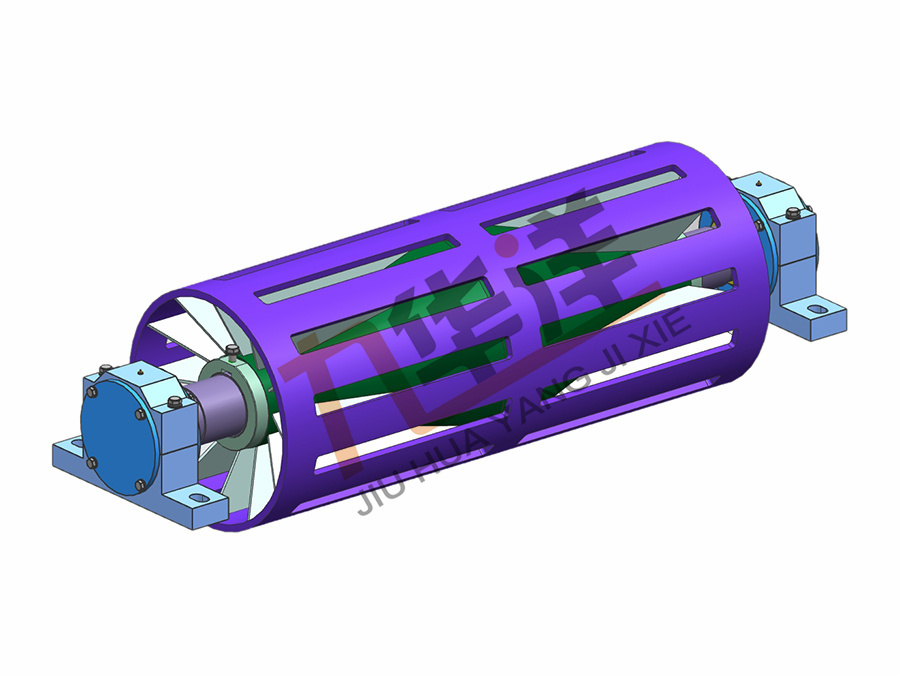

Spoke-type waist-drum-shaped slag-discharge roller

This product can especially serve as the bend roller and counterweight roller of bucket-wheel reclaimer in coal mine, iron and steel raw material plant, wharf stockyard, power plant and coal yard . When there are more materials on the return conveyor belt, the materials can be discharged from it.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Performance introduction

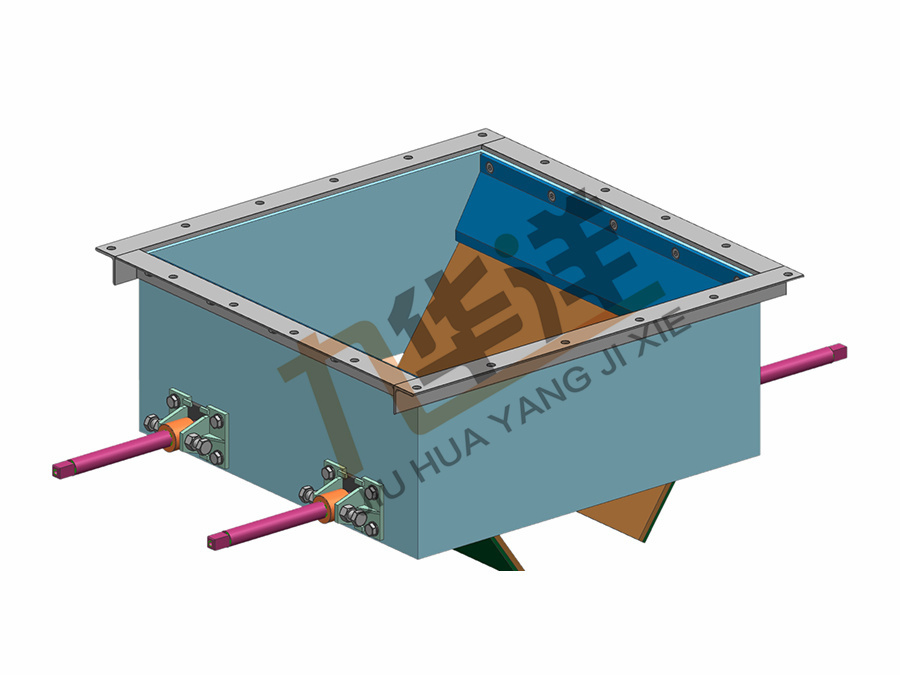

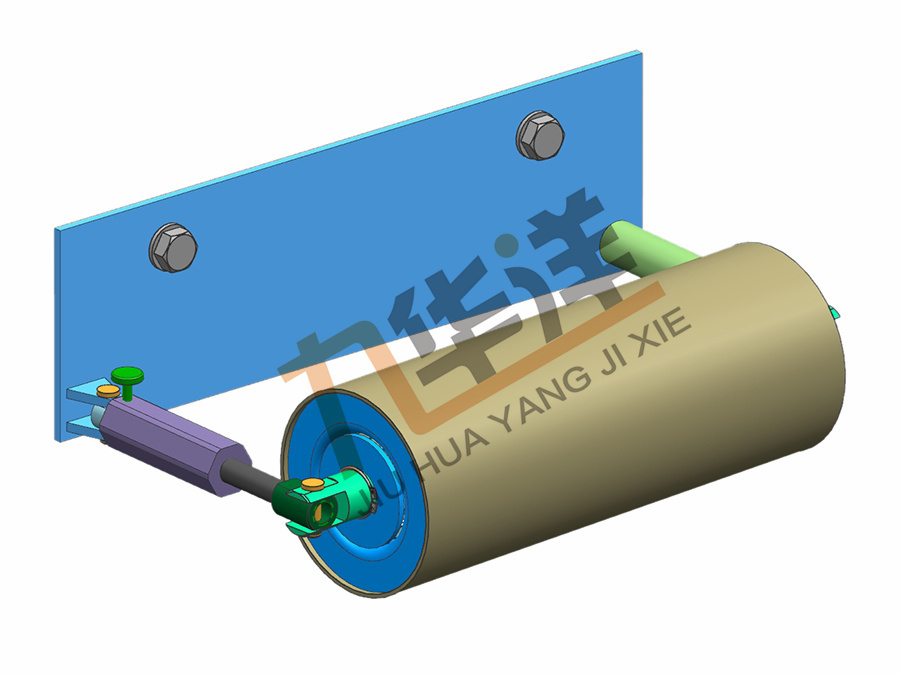

Both ends of drum-shaped slag-discharge roller are provided with inverted cone structure, and the contact surface has a spoke-shaped structure, which is convenient for removing large materials. Polyurethane elastomer wear-resistant material is coated on the spoke-shaped working face by special technique, which is beneficial to improving wear-resistant performance and cleaning effect, and completely protects the roller and tape. The contact surface adopts a drum-shaped structure, which can play a role in correcting deviation.

Application field

This product can especially serve as the bend roller and counterweight roller of bucket-wheel reclaimer in coal mine, iron and steel raw material plant, wharf stockyard, power plant and coal yard . When there are more materials on the return conveyor belt, the materials can be discharged from it.

Main characteristics

◎ Good cleaning effect: The slag-discharge roller is used as the tail roller or tensioning roller, which has a good cleaning effect on the materials on the conveyor belt;

◎ Good sealing performance: The slag-discharge roller rotates around the bearing seat at the end, and the bearing seat is sealed and designed to ensure the sound operation of the roller;

◎ Good strength: The thickness of slag-discharge roller rib plate is 12-15mm, and that of wing plate contacting conveyor belt is 12-20mm, and the width of single wing is 80mm;

◎ Excellent material: Polyurethane elastomer composite wing plate can be selected to protect the conveyor belt better;

◎ Wide adaptability: It can operate in harsh environment, including dry and wet conditions, and can provide flame retardance for underground use;

◎ Serialized products: Roller’s diameter, effective length and other dimensions can be customized to meet arbitrary specifications for belt width within 500-2400mm.

Model selection

JHYPZG belt width-roller diameter-wing plate material (PU/Mn)

They are in order as follows: Tape width, roller diameter, and used materials (PU meaning the wing plate is made from polyurethane elastomer composite material; Mn meaning the wing plate is made of all steel).

Polyurethane drum-shaped slag-discharge roller JHYPZG-PU series

The spoke-shaped working face is coated with polyurethane elastomer wear-resistant materia by pouring process and is vulcanized to improve wear resistance and increase friction coefficient.

Steel drum-shaped slag-discharge roller JHYPZG-Mn series

The surface of the roller is provided with a long hole parallel to the axial direction. When the materials get onto the return belt has materials, they can enter into the inside of roller through the long hole. There is a double cone with two sharp ends and thick middle inside the roller. The two ends of the roller are provided with holes. The materials enter the roller after passing through the axial long hole on the surface of the roller, and are discharged to the stockyard after passing through the vertebral body and holes at both ends.

Steel final assembly of slag-discharge roller

Steel final assembly of slag-discharge roller

Previous page

Previous page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO