Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

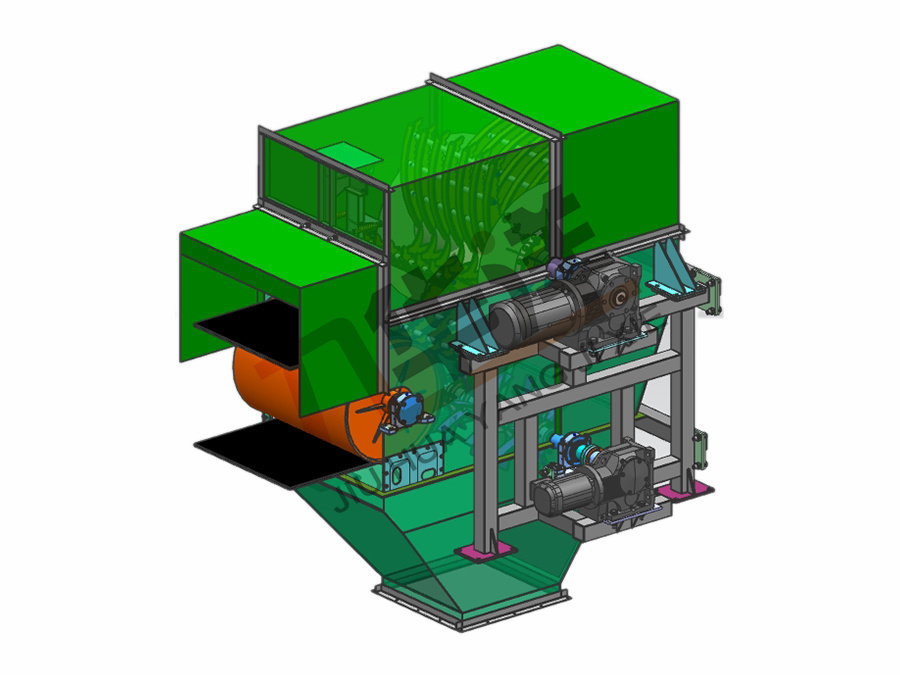

Toothed multistage mixer(0~600mm)

A variety of different quality bulk materials are mixed in the conveyor belt through the stacker and reclaimer. Because the bulk materials of different quality are not fully mixed, there will be stratification on the belt. The existing traditional mixing equipment, covering a large area, low mixing efficiency, can not be suitable for large flow, harsh conditions.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Technical background

A variety of different quality bulk materials are mixed in the conveyor belt through the stacker and reclaimer. Because the bulk materials of different quality are not fully mixed, there will be stratification on the belt. The existing traditional mixing equipment, covering a large area, low mixing efficiency, can not be suitable for large flow, harsh conditions.

Brief introduction of structure

It is mainly composed of a primary mixing mechanism, a secondary mixing mechanism, a tertiary mixing mechanism, a T-shaped parabolic tooth plate, a fan-shaped deflector, a cross spiral impeller, a frame type driving rotor, a decelerating motor, an elastic support, a dust curtain, a sealing device, a box, a frame and an electric control cabinet. Electric control system full frequency control, wide range of adaptation. Adopt explosion-proof motor, multiple safety protection of moving parts. The control cabinet is made of double-layer stainless steel shell, fully sealed structure, waterproof and dust-proof.

Component introduction

The first level mixing mechanism is connected by the triangular guide body through the bolt and the guide regulating column, the guide regulating column is fixed on the guide frame, the guide frame is suspended by the guide hinge shaft at the entrance of the left box after the louver type dust curtain. The other end of the spring is connected to the slip-knot bolt on the upper left box. By adjusting the upper and lower position relationship between the regulating column and the triangular guiding body, the shape of the material flow section is adjusted.

The full floating main rotor is composed of a T - shaped parabolic tooth plate, a driving drum, a reduction motor, a support, etc. The long flange shaft on the drum assembly is connected with the reduction motor, and the T-shaped parabolic tooth plates are arranged in rows according to the set spacing, and the rows are crossed with the adjacent rows along the circumference. The T-shaped parabolic tooth plate is arranged cross between rows along the circumferential direction, forcing the material flow away S shape, prolongs the contact time between the material and the rotor, and strengthens the mixing effect.

Three level head mixing mechanism, mainly for moisture content ≥15% of wet materials. Wet and viscous materials are easy to adhere to the impact surface of the hopper. In order to prevent excessive accumulation of materials, cross spiral impeller with left and right rotating blades is set. Positive rotation, the material from both ends to the center of the collection. When reversed, the material is dispersed from the center to both ends. Positive turn + delay + reverse, play the role of forced cleaning and transverse stirring. According to the material properties, mixing degree, moistening degree, programmable setting speed, spin, time and other parameters of different combinations, to achieve the goal of full mixing.

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO