Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

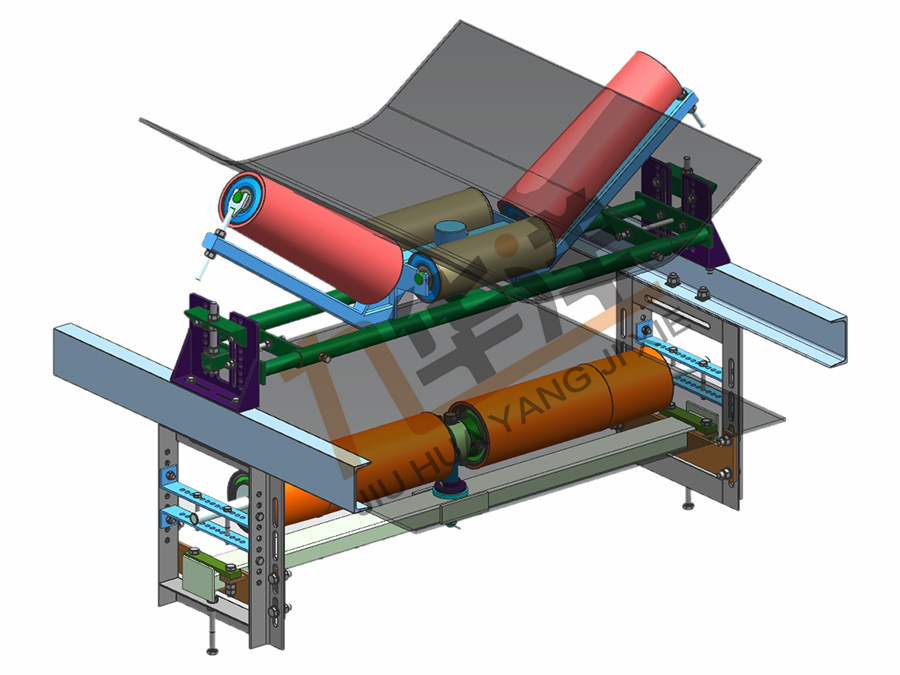

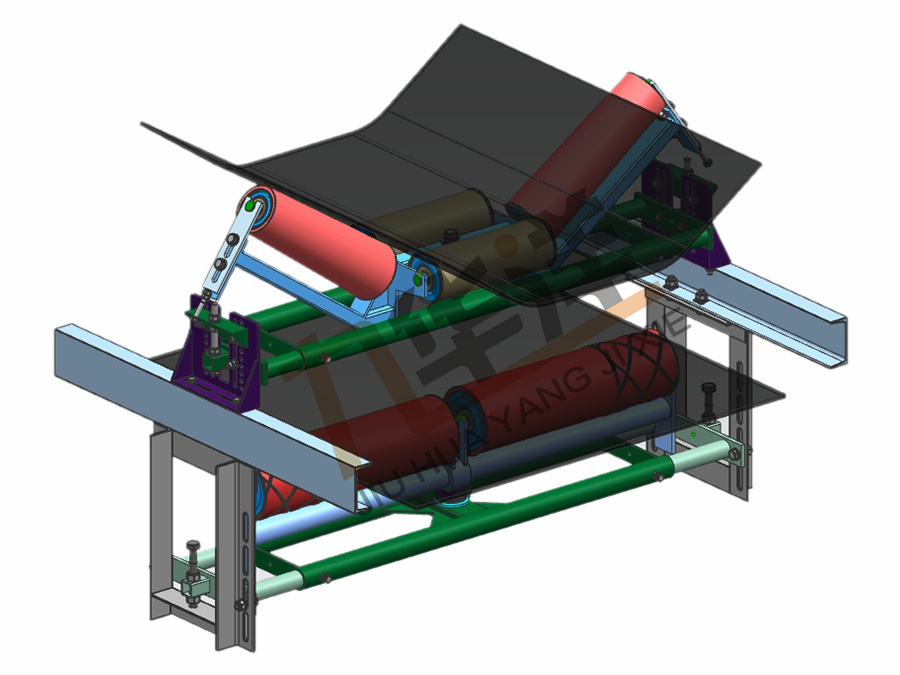

Torsion correction device of tubular belt conveyor

Typical applications of pipe conveyor: closed continuous transportation of various loose materials and small and medium-sized materials in industries such as power, coal, metallurgy, mining, ports, grain, building materials, chemical engineering, etc.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Performance characteristics of tubular belt conveyor

◎ Closed conveying, avoiding foreign matter invasion and material loss, capable of environmental protection;

◎ Spatial three-dimensional turn, no need for transfer station and no deviation;

◎ Using the friction principle, the transmission with large inclination angle can be realized, which can generally reach 45°;

◎ Using Janssen's theorem and the side extrusion effect of special belt, 90° vertical lifting can be realized and the direction can be changed in a small radius;

◎ The lower branch can be used to reversely transport materials different from that on the upper branch (special feeding device should be set);

◎ Reducing driving devices cuts total system power and fault points.

Deviation and torsion correction

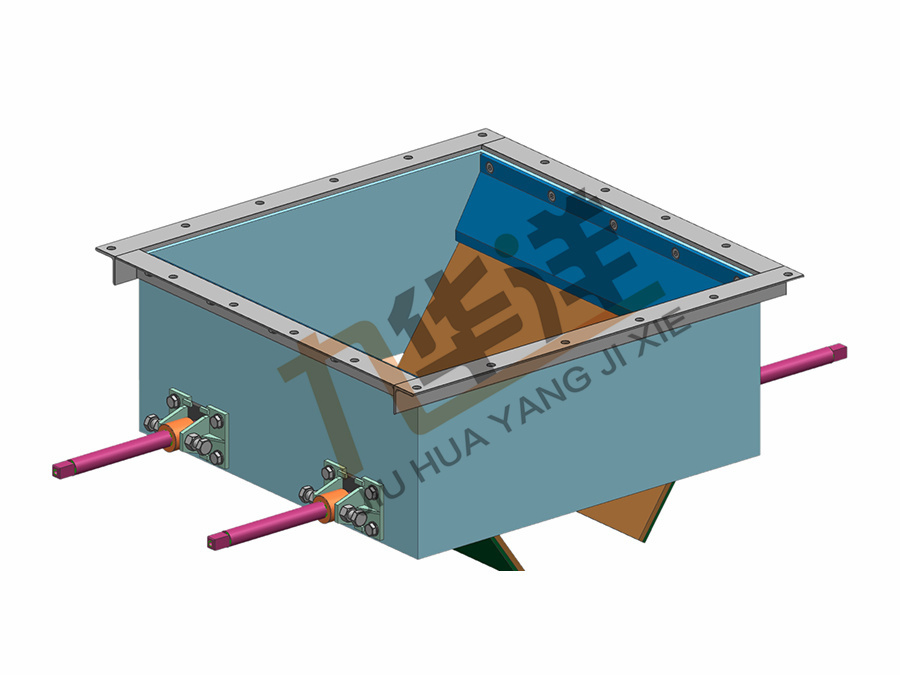

◎ The belt receiving point adopts curve anti-blocking blanking pipe technology to ensure the blanking point alignment (or install material flow correction and alignment device), which is beneficial for the belt to form pipe;

◎ The rated material flow control device is designed for the outlet of the guide trough at the material receiving point to ensure continuous and even feeding and avoid the occurrence of pipe expansion;

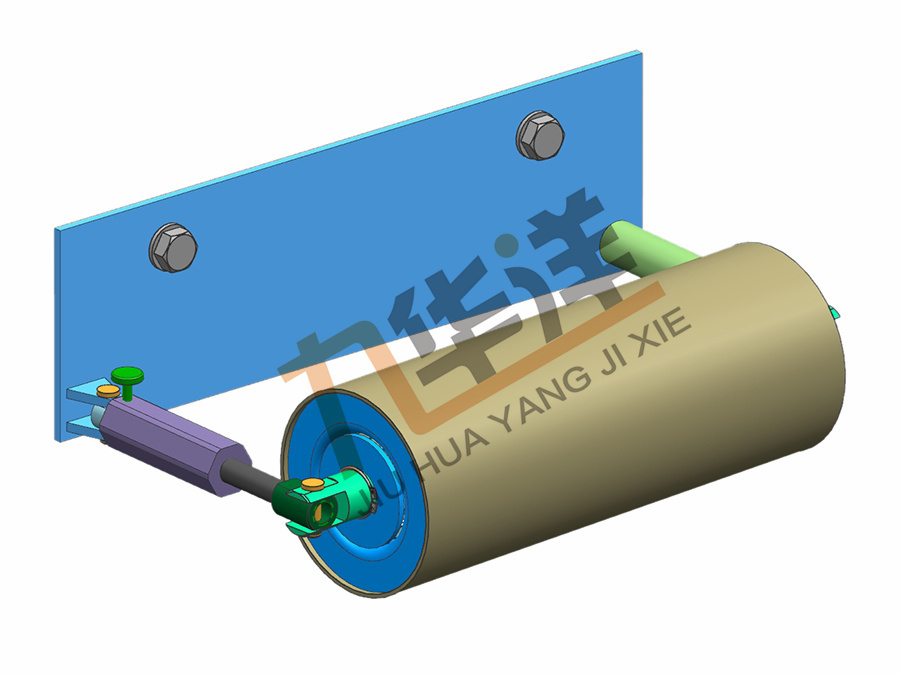

◎ Jiuhuayang JHY maintenance-free corrector is installed at special key points such as head and tail belt sections, driving, steering, tensioning and blanking to ensure complete control of belt to make it run in the center of the rack;

◎ JHY special correction idler should be installed continuously before climbing, turning and other parts of belt where tubular tape is prone to deviation and torsion.

◎ In the process of load test run, if the conveyor belt can not be smoothly swithced to pipe in the bearing section, the trough angle and position of the transition idler group in the back transition section shall be adjusted; and the height and front and back positions of the side pressing idler in the back transition section shall be adjusted.

◎ In the process of load test run, if the conveyor belt can not be swithced to pipe smoothly in the return section, the height and front and back positions of the side pressure idler in the front transition section shall be adjusted; and the height and left and right positions of the pressure idler and the supporting idler in the front transition section shall be adjusted.

◎ In the process of load test run, if the tubular conveyor belt twists or even turns over, the lower idler at the front section of twisted belt is continuously replaced with the special self-balancing idler of Jiuhuayang, which can ensure the automatic alignment of the tubular belt; or the angle of the annular idler on the seat plate can be manually adjusted, and the adjustment direction is opposite to the turning direction.

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO