Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

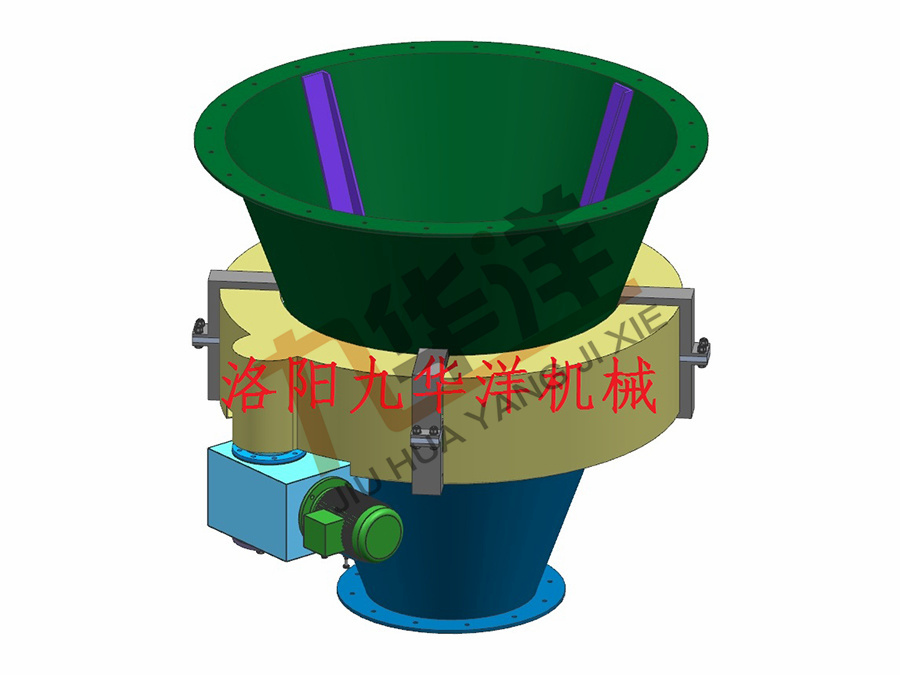

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

Controlled air pressure type clog-removing machine

Scope of application: rotary warehouse, square warehouse, steel, cement matrix warehouse, can be used.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Basic principle

◎ High pressure air is sprayed into the silo by several nozzles close to the silo wall according to the spiral line, forming a whirlwind airflow in the silo, which can temporarily isolate the material from the silo wall, reduce the friction resistance of the material in this section, and eliminate the phenomenon of sticking to the wall. At the same time, in the process of air rotation, a low pressure area is formed in the middle of the air flow in the bin, and the material collapses under its own gravity, destroying the roof material in the bin.

◎ Reduce the friction between materials and warehouse wall, and reduce the friction coefficient between materials and warehouse wall.

◎ Reduce the cohesiveness of materials, blow and crush into clusters of materials, causing material disturbance in the warehouse, force imbalance, natural collapse.

Technical characteristics

◎ The nozzle position is flexible and changeable, the nozzle type is changeable, and the blocking energy is evenly distributed, which can eliminate the arched shed material while removing the sticky wall.

◎ PLC control, can realize the ventilation pressure, injection sequence, ventilation flow, interval time, ventilation cycle change and other random adjustment, to meet different working conditions; Can realize manual/automatic, local/centralized control, and can be quickly converted;

◎ Preventive plugging removal can be carried out by setting. Before the flow of materials weakens or deteriorates, the plugging removal work can be started at a fixed time to avoid the occurrence of material plugging;

◎ The intensity of air injection remains basically unchanged in the process of air injection. In one time plugging removal, multiple discharge impulse peaks can be realized by PLC, which can make the air flow pulsate and oscillation, eliminating the formation of rat holes;

◎ Flow aid air source (≥0.4MPa) and control air source are separated by the lowest pressure holding valve, in the process of flow aid can keep the pressure of the gas network stable;

◎ No moving parts, no obstacles in the warehouse;

◎ Strong reliability, high efficiency, only a few seconds to complete the cleaning;

◎ Can replace vibration hammer vibration break arch, air cannon blowing break arch.

◎ Installation can not be cleared, suitable for the technical transformation of the old and new silo;

Basic parameter

◎ Power supply :AC220V/AC380V,50HZ;

◎ Air source pressure 0.4 ~ 1.0Mpa, exhaust volume: 1 ~ 6m3/min

◎ Air storage tank: volume 3-15m3, pressure 0.8 ~ 1.0Mpa

Scope of application

Revolving bin, square bin, steel, cement matrix bin, can be used.

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO