Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

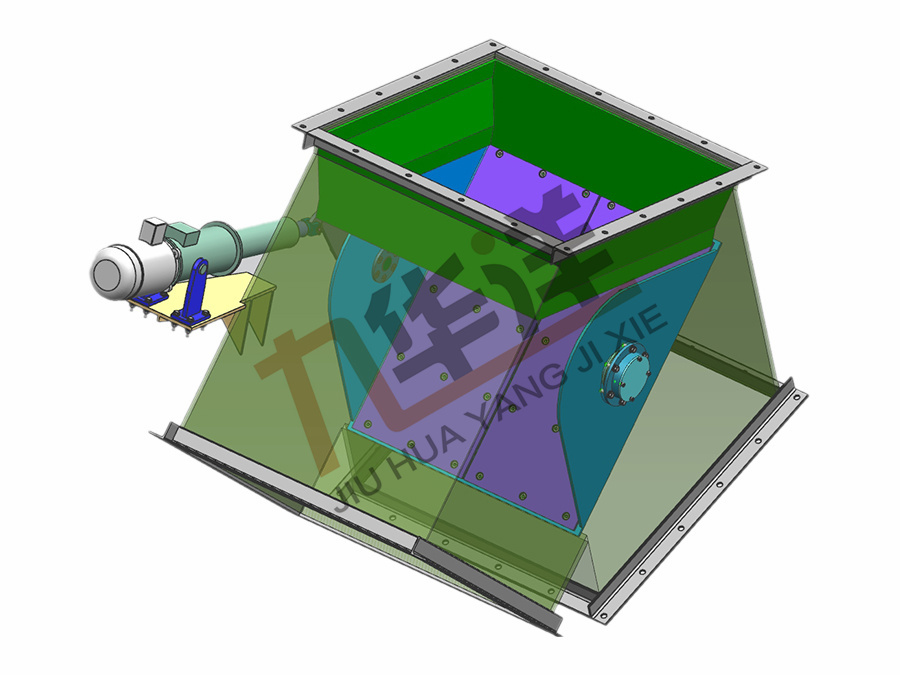

Plough type unloader

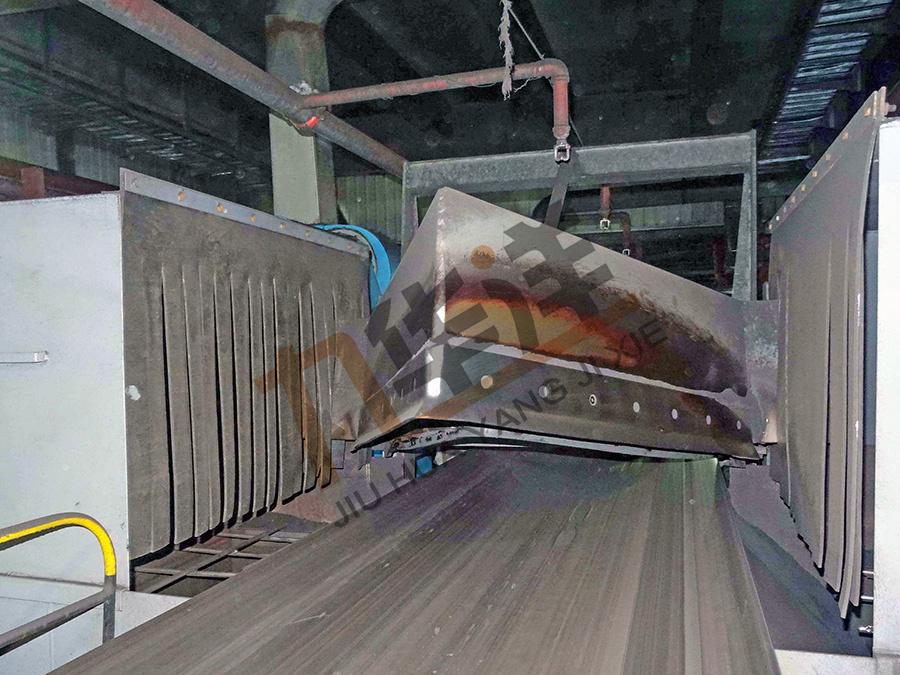

Electric (hydraulic) dynamic variable slot Angle plow unloader is based on electric (hydraulic) dynamic push rod as power source. When working, it extends through the push rod to drive the plow bed forward to complete the fall of the plow, and supports the flat roller set, so that the working face of the belt is straight, the lower edge of the head is closely fitted with the belt surface, and the material on the belt is discharged into the air lock funnel on both sides. In non-working state, start the electric push rod to retractable the driving rod, drive the plow bed to back up, and the variable idler set changes from parallel to groove shape, so that the material can pass smoothly.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Working principle

Electric (hydraulic) dynamic variable slot Angle plow unloader is based on electric (hydraulic) dynamic push rod as power source. When working, it extends through the push rod to drive the plow bed forward to complete the fall of the plow, and supports the flat roller set, so that the working face of the belt is straight, the lower edge of the head is closely fitted with the belt surface, and the material on the belt is discharged into the air lock funnel on both sides. In non-working state, start the electric push rod to retractable the driving rod, drive the plow bed to back up, and the variable idler set changes from parallel to groove shape, so that the material can pass smoothly.

Main characteristics

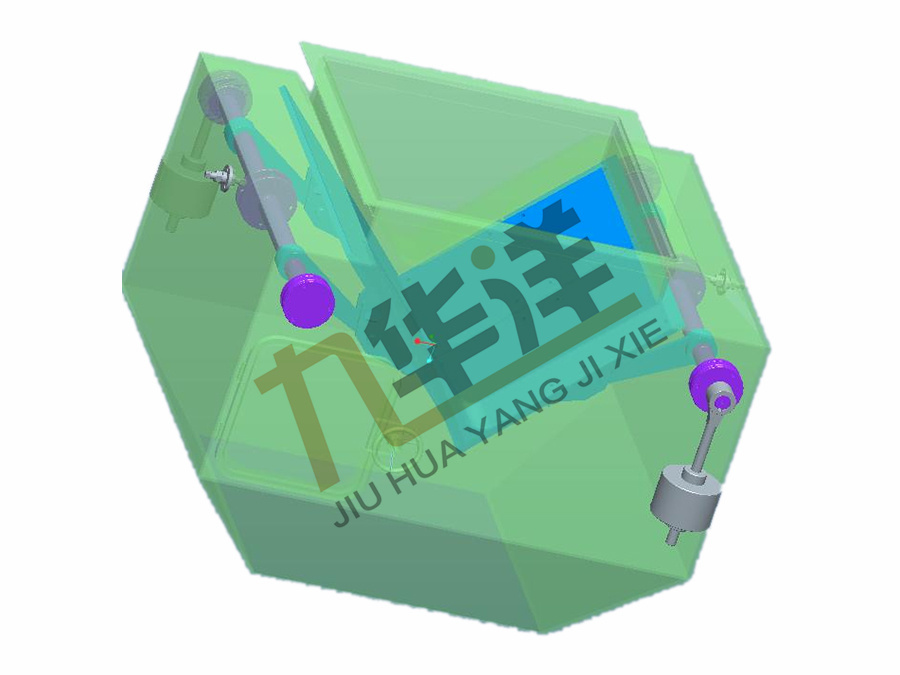

◎ The main plow is responsible for unloading most of the materials, and the auxiliary plow is responsible for cleaning the remaining materials of the main plow, so that the discharge is more clean and thorough.

◎ The ploughshares can be adjusted up and down, so that the installation or ploughshares wear compensation adjustment is convenient.

◎ The electric (hydraulic) moving push rod can be mounted overhead (placed above the belt) or side (placed on the side of the belt).

◎ Steady discharge without shaking.

◎ It can easily realize local operation and centralized control.

Main technical parameters and selection table

|

NO. |

Specification and model |

Adaptive bandwidth(mm) |

thrust(N) |

speed(mm/s) |

weight(Kg) |

|

1 |

JHYLXLQ-500 |

500 |

5000 |

40 |

810 |

|

2 |

JHYLXLQ-600 |

600 |

5000 |

40 |

890 |

|

3 |

JHYLXLQ-800 |

800 |

7000 |

40 |

1000 |

|

4 |

JHYLXLQ-1000 |

1000 |

10000 |

40 |

1100 |

|

5 |

JHYLXLQ-1200 |

1200 |

10000 |

40 |

1280 |

|

6 |

JHYLXLQ-1400 |

1400 |

15000 |

35 |

1400 |

|

7 |

JHYLXLQ-1600 |

1600 |

15000 |

35 |

1550 |

|

8 |

JHYLXLQ-1800 |

1800 |

20000 |

35 |

1700 |

|

9 |

JHYLXLQ-2000 |

2000 |

20000 |

35 |

1850 |

|

10 |

JHYLXLQ-2200 |

2200 |

25000 |

35 |

2050 |

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO