Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

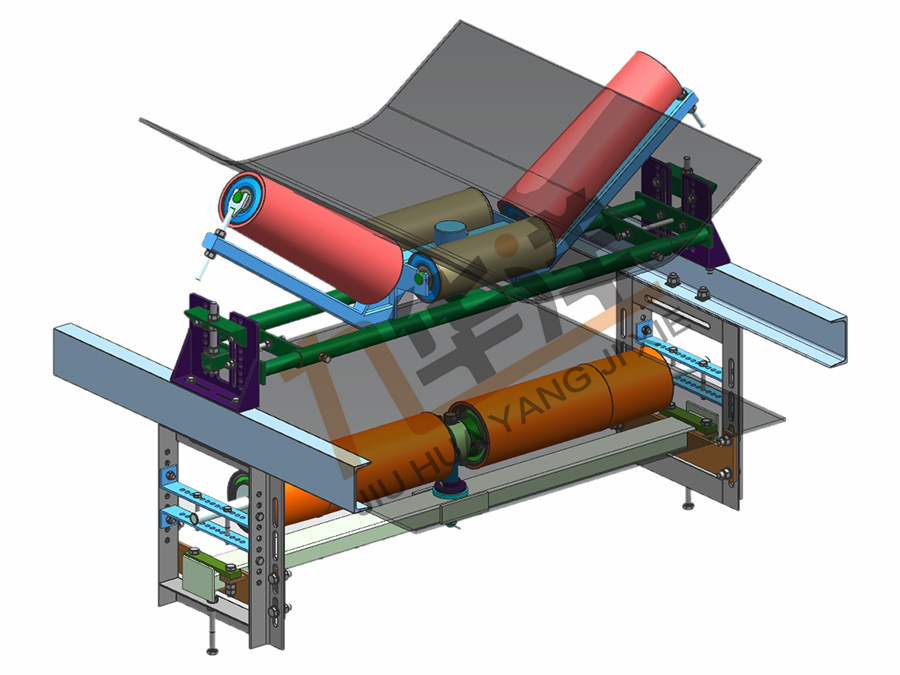

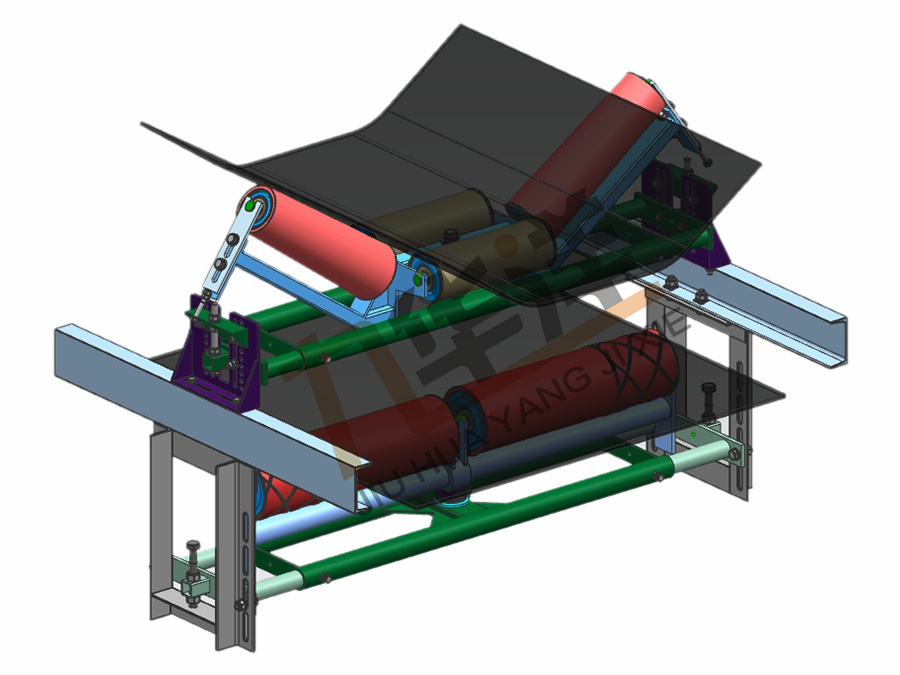

Tape longitudinal tear protection device

In the process of conveying materials by belt conveyor, materials, sundries or metal parts may scratch or penetrate the conveyor belt, and the steel wire rope core conveyor belt may cause longitudinal tearing accident, which will bring great losses to your property and safety.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Main uses and scope of application

In the process of conveying materials by belt conveyor, materials, sundries or metal parts may scratch or penetrate the conveyor belt, and the steel wire rope core conveyor belt may cause longitudinal tearing accident, which will bring great losses to your property and safety.

The longitudinal tearing monitoring device of conveyor belt is capsule type, which can reliably send out alarm signal and stop signal when the conveyor belt tearing accident occurs, to stop the continuous development of the accident in time. It is suitable for the safety protection of belt conveyor in various industries.

Main technical indicators

|

Model |

V model |

P model |

|

Operating voltage of control box |

AC 220V 50HZ |

|

|

Switch contact capacity |

AC 220V 3A |

|

|

Number of switch contacts |

1 Normally open (customizable) |

|

|

Protection grade |

Control box IP54 |

|

|

Sensor IP65 |

||

|

Reset mode |

Manual button reset |

|

|

Operating environment |

Operating temperature-30~+40℃ |

|

|

Relative humidity≤90% (25℃时) |

||

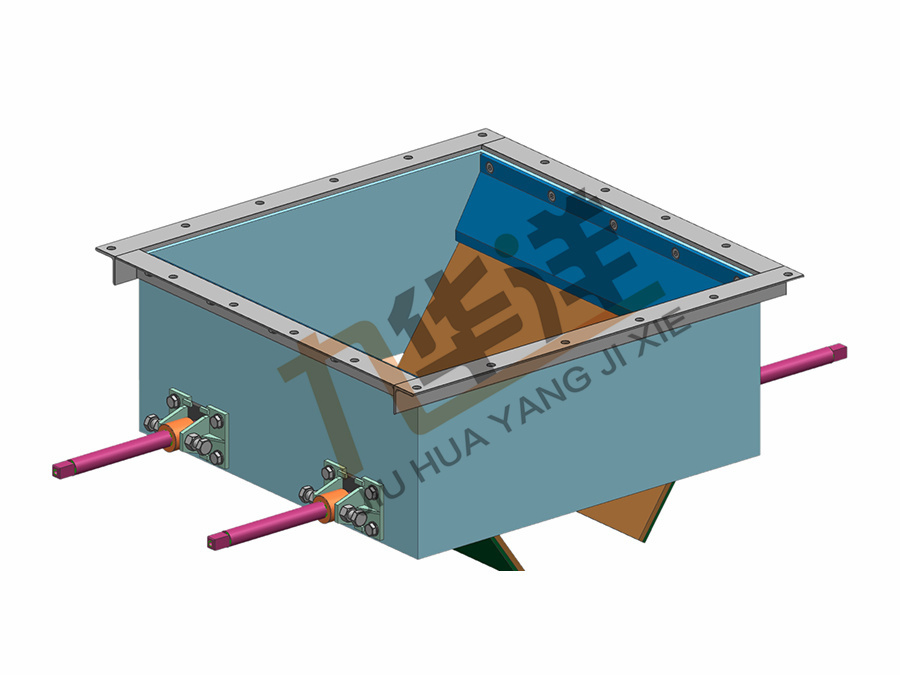

Working principle and performance

The capsule-type longitudinal tearing monitoring device consists of sensor and control circuit. The sensor is a detecting element for longitudinal tearing, When the conveyor belt is penetrated by foreign materials, the sensor is squeezed as the conveyor belt moves foreward, or when the sensor arranged at the discharge port is squeezed due to material blockage between the chute discharge port and the conveyor belt, the sensor can sensitively and reliably detect the tearing signal of the conveyor belt, output the switching value and send out the stop signal. The control circuit has delay function.

Power indicator lamp and alarm indicator lamp are the same lamp. After being electrified, it is always on as power indicator lamp and flashing as alarm indicator lamp.

After power-on, the indicator light is always on, indicating that the power supply is normal. Press the self-calibration button, and the indicator light flashes. At the same time, measure the output switching value conversion.

Then press the reset button, the indicator light is always on, and the output switching value is reset, indicating that the control box is normal.

The device has the following characteristics

(1) Convenient installation;

(2) The sensor of the detection element has strong sealing performance and can be used under harsh conditions;

(3) The panel of the control box is provided with a self-calibration button. When the self-calibration button is pressed, the field fault can be simulated and the tearing alarm function mentioned above can be realized.

Special control alarm instrument

Semiconductor planar light-emitting device, with high brightness, soft color, low power consumption, parallelly driven and long working life.

It can communicate bidirectionally with various detection and control instruments, PLC DO point, PLC serial port, touch screen, industrial personal computer and other equipment with communication interface, and form a monitoring system, using standard ModBUS-RTU communication protocol (international common).

It is designed according to international standard procedures; can also be made according to user requirements; and has alarm memory function.

There are buzzer, test and silencing buttons inside the instrument, and there are external buzzer interface (passive contact signal) and test and silencing button interface.

The instrument has clamp-in structure design and is compatible with demestice XXS series flash signal alarm, which is convenient for installation, maintenance and replacement.

Instrument power supply AC220V.

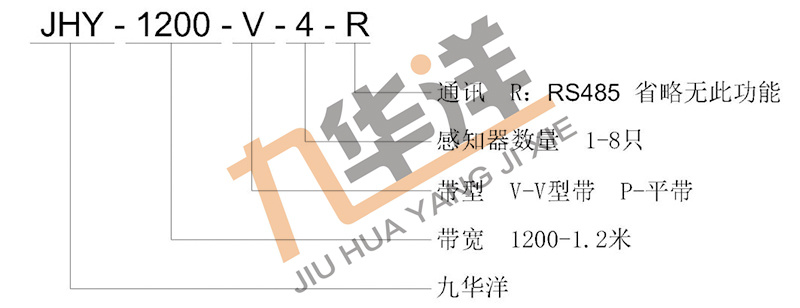

Mode of selection

Model explanation JHY-1400-V-4-R (i.e., 1.4m width of belt, V-shaped belt, 4 intelligent sensors, with RS485 communication function)

Installation site

Tape longitudinal tear-resistance (trough type)

Tape longitudinal tear-resistance (Flat type)

Tape longitudinal tear-resistance (Installation site)

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO