Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

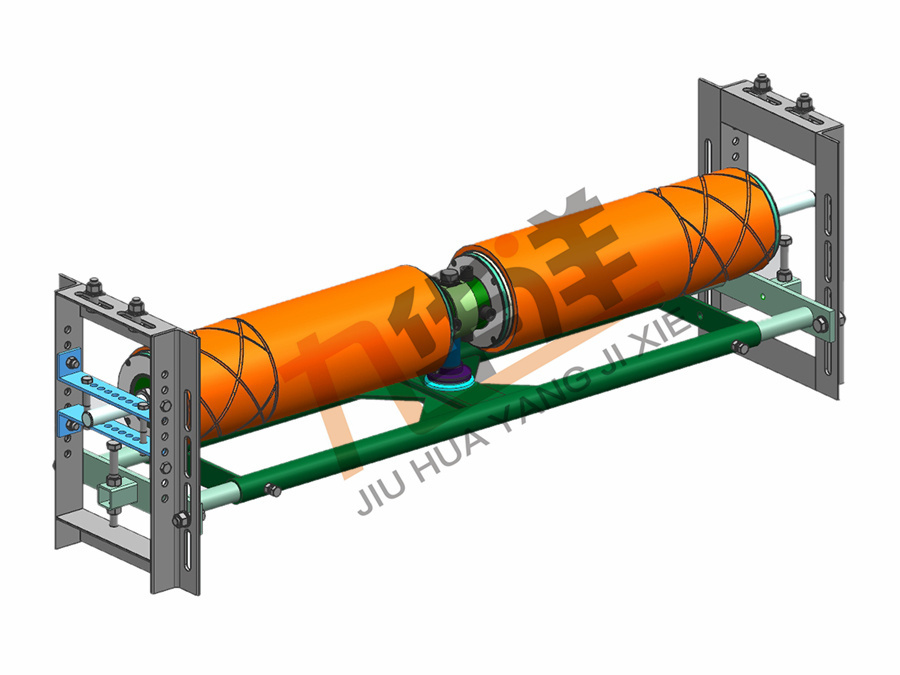

JHY maintenance-free corrector(Automatic pre-correction)

Typical application fields of JHY maintenance-free corrector: hyper-cold, hyper-heat, port, humidity, plum rain, open air, underground, corrosion, gobi, desert, dust and other harsh working conditions. JHY maintenance-free corrector can stand the test, providing fully automatic and all-day protection for the safe and civilized operation of your belt conveyor!

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

【Application field】

◎ Coal mine, electric power, mining, metallurgy, port, chemical industry, building materials, grain and other occasions where belt conveyor is used;

◎ Bucket wheel machine cantilever (portal bucket wheel machine), and tail car two-way reversible belt conveyor;

◎ Tension section of telescopic head and tail of two-way reversible belt conveyor in stacking yard;

◎ Movable and fixed two-way belt conveyor;

◎ Open-air, wet-resistant short belt conveyors for ship loaders and ship unloaders;

◎ Underground steel-pipe quick-disassembly and quick-loading belt conveyor:

◎ Large inclination corrugated side belt;

◎ Curve turning belt conveyor;

◎ Various unidirectional belt conveyors;

【Problem solving】

Jiuhuayang maintenance-free corrector can automatically and effectively solve belt deviation caused by the following reasons:

◎ Under various dynamic conditions such as downward tilting, upward tilting, rotation, no load, load, feeding and blanking, the lateral stress of bucket turbine cantilever changes abnormally, and the common aligning idler can not automatically correct the deviation in time, resulting in belt deviation;

◎ Bucket on cantilever of bucket wheel machine is easy to collide with material pile, and the frame is seriously deformed, resulting in belt deviation;

◎ Materials are caught in the cantilever’s head roller of the bucket wheel machine, resulting in uneven wear, further resulting in belt deviation;

◎ Bucket wheel machine’s walking guide rail is not parallel to the center line of trestle two-way belt conveyor, creating lateral resistance, further resulting in belt deviation;

◎ Two-way reversible belt of gantry bucket wheel machine (3-stage type) usually can deviate due to the problem of blanking point;

◎ The rough installation base, deformation of frame and large change of blanking point of underground steel-pipe quick-disassembly and quick-loading belt conveyor can lead to belt deviation;

◎ Large inclination corrugated side belt is installed vertically, resulting in belt conveyor deviation.

◎ For the curve turning belt conveyor, the inclination angle at the turning is set unreasonably, and the lateral force is uneven, which leads to belt deviation;

◎ Because of a large amount of rainwater mixed in the open-air belt, the friction between the belt and the idler drops sharply, resulting in belt deviation;

◎ In winter, when ice and snow are mixed, the temperature drops, the belt hardens, the friction resistance decreases, and it is easy to slip, which leads to the belt deviation;

◎ Drive roller rubber is improper or falls off, and the sides of both ends of the roller are inconsistent, resulting in transverse component, further resulting in belt deviation;

◎ The transported materials are sticky and wet, the sweeper can't completely scrape the belt, and materials are caught in the roller, resulting in belt deviation;

◎ There are many large pieces of materials transported, and the particle size difference is large, which greatly changes the impact force on the belt, resulting in belt deviation;

◎ The flow rate of transported materials is unstable, being too big and too small, and machine starts frequently, resulting in belt deviation;

◎ The dynamic change of multi-point receiving materials produces transverse impact on the belt, which influences mutually, resulting in belt deviation;

◎ The blanking point is not correct, and an effective material flow correction device is not installed, resulting in belt deviation;

◎ Drive roller, idler, guide trough, etc., are improperly installed, resulting in belt deviation;

◎ The surface collapses, the foundation sinks, and the frame is skewed, resulting in belt deviation;

◎ The counterweight and tensioning mechanism have unbalance loading, resulting in belt deviation;

◎ The belt joint is not straight, resulting in belt deviation;

◎ ......

Regardless of variaties of belt, such as bidirectional reversible belts on bucket wheel machine cantilever, gantry bucket wheel machine (3-stage), bucket wheel tail car, and stockyard,, and one-way belts on underground steel-pipe quick-disassembly and quick-loading belt conveyor, large inclination corrugated side belt, ship loader, ship unloader, as well as curve turning belt on conveyor, the belt can basically run normally in the center of the rack, with Jiuhuayang maintenance-free corrector reasonably installed.

【Technical characteristics】

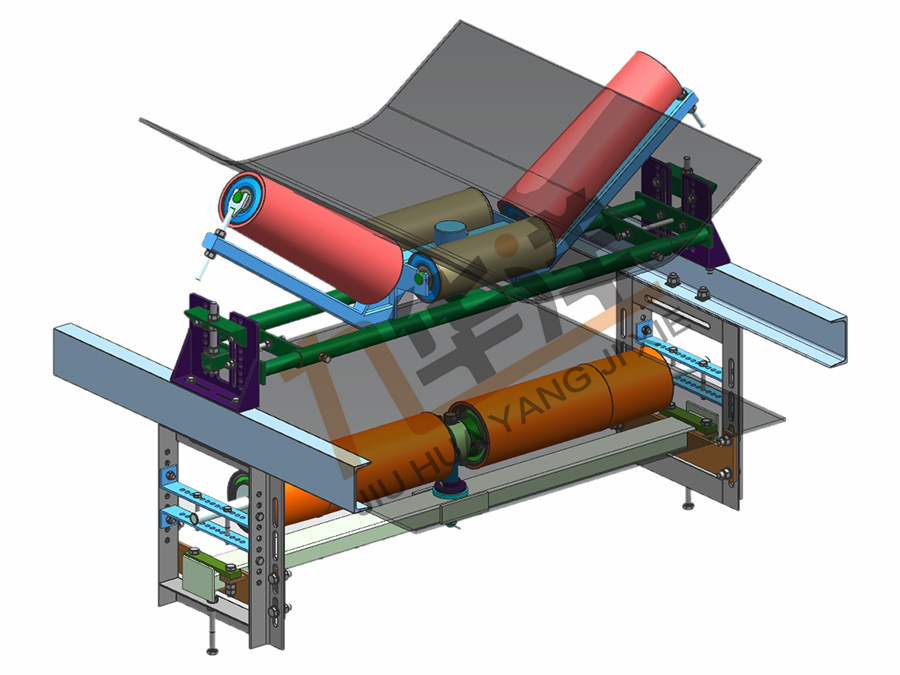

◎ The middle idler controls the moving direction of the belt, and the idlers on both sides will not damage the edge of the belt;

◎ Special structural design: The central rotating shaft will not be stuck and will not vibrate when working;

◎ Using the reaction force produced by the belt deviation tendency to correct and rebalance it;

◎ Quick and immediate correction, and synchronous response, with no need for power actuators;

◎ Automatic balancing, convenient installation, reliable performance and durability;

◎ It can be used for two-way reversible/one-way/turning belts with strong resistance to (damp heat, hyper-cold, dust, corrosion, etc.).

【Structural principle】

◎ Special structure and action mechanism: The whole set of parts are all precision machined by numerical control (or special) machine tools;

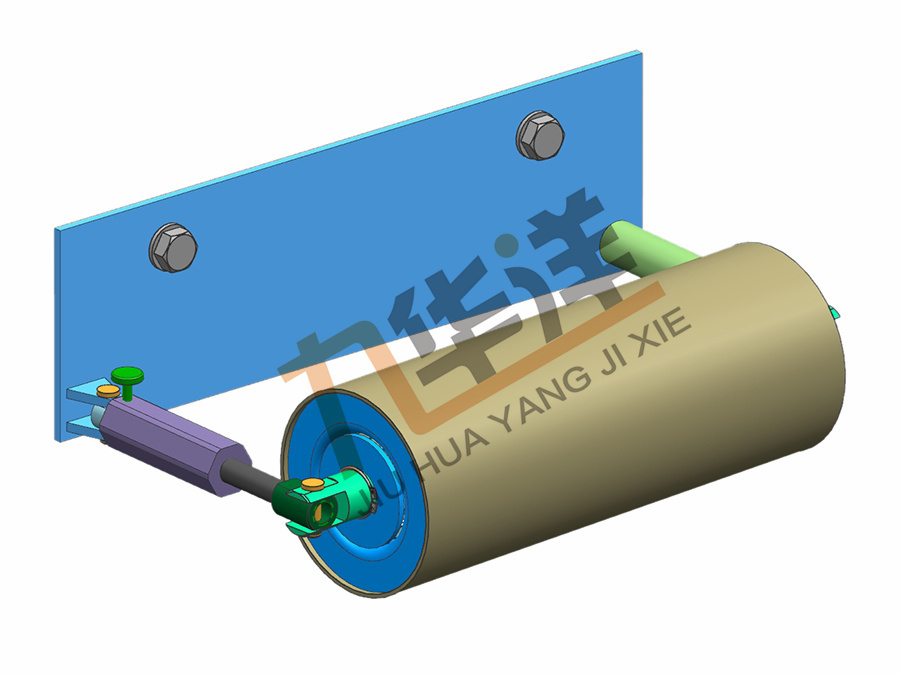

◎ The outer layer of idler is covered with super wear-resistant composite materials, and the cone sections at both ends have sensing patterns, which are cast as a whole;

◎ It is equipped with automatic self-lubricating device made from stainless steel composite wear-resistant material, which is maintenance-free;

◎ Multiple seals such as machinery, rubber and liquid are adopted to adapt to resist the harsh working environment such as damp heat, hyper-cold, dust and corrosion;

◎ The application effect is not affected by bad working conditions such as open air, wet and slippery during rainy season, cold and freezing, serious dust pollution and underground humidity.

【Classification】

◎ Heavy duty maintenance-free corrector ( for heavy belt conveyor with large capacity for coal or ore)

◎ Standard maintenance-free corrector (for national standard DTII, DTI, DT75 belt conveyor)

◎ Light maintenance-free corrector (for light belt conveyor for tobacco, food, fertilizer, building materials, etc.)

【Installation quantity and location】

Install JHY maintenance-free corrector at about 3 times width of belt in front of the position where the belt is prone to deviation;

On group of curve-turning belt conveyors are installed every 20m on average (except for special key points such as sharp bending, driving, steering, tensioning and blanking).

One group of two-way belt conveyors such as bucket wheel machines are installed every 20m on average (except for special key points such as driving, steering, tensioning and blanking).

One group of one-way short belt conveyors are installed every 30m on average (except for special key points such as driving, steering, tensioning and blanking).

On group of one-way long belt conveyors are installed every 50m on average (except for special key points such as driving, steering, tensioning and blanking).

【Precautions in installation】

◎ JHY maintenance-free corrector can be adjusted in relative range such as up and down, left and right, front and back angles, etc., which is suitable for on-site installation size;

◎ The installation hole of original ordinary idler or ordinary deflection adjustment device canbe used, which need to be in the transverse section of the belt conveyor, not beyond its range;

◎ JHY higher contact point between maintenance-free corrector primary idler and belt shall be 10-15mm higher than that between ordinary idler and belt;

◎ The JHY maintenance-free corrector is completely installed bilaterally symetrically, taking the centerline of the belt conveyor rack as the baseline;

◎ The JHY maintenance-free corrector spindle axis is completely perpendicular to the belt moving centerline direction in front and back;

◎ The inclination angle of the induction idler on both sides of JHY troughing maintenance-free corrector can be adjusted, and the contact length with belt is 50-100mm;

◎ For JHY double-return maintenance-free corrector, its swing range can be controlled by adjusting screws, and the stop lever must not be forcibly fixed.

◎ JHY maintenance-free corrector has mechanical automatic deviation adjustment function; and after installation and adjustment, non-professionals shall not intervene in its operation at will.

Common specification selection of two-way reversible JHY maintenance-free corrector :

|

Name |

Type of troughing working section |

Type of flat return section |

Applicable width of belt |

|

Two-way reversible JHY maintenance-free corrector |

JHYJZP650AD-B |

JHYJZP650BD-B |

650 |

|

JHYJZP800AD-B |

JHYJZP800BD-B |

800 |

|

|

JHYJZP1000AD-B |

JHYJZP1000BD-B |

1000 |

|

|

JHYJZP1200AD-B |

JHYJZP1200BD-B |

1200 |

|

|

JHYJZP1400AD-B |

JHYJZP1400BD-B |

1400 |

|

|

JHYJZP1600AD-B |

JHYJZP1600BD-B |

1600 |

|

|

JHYJZP1800AD-B |

JHYJZP1800BD-B |

1800 |

|

|

JHYJZP2000AD-B |

JHYJZP2000BD-B |

2000 |

|

|

JHYJZP2200AD-B |

JHYJZP2200BD-B |

2200 |

|

|

JHYJZP2400AD-B |

JHYJZP2400BD-B |

2400 |

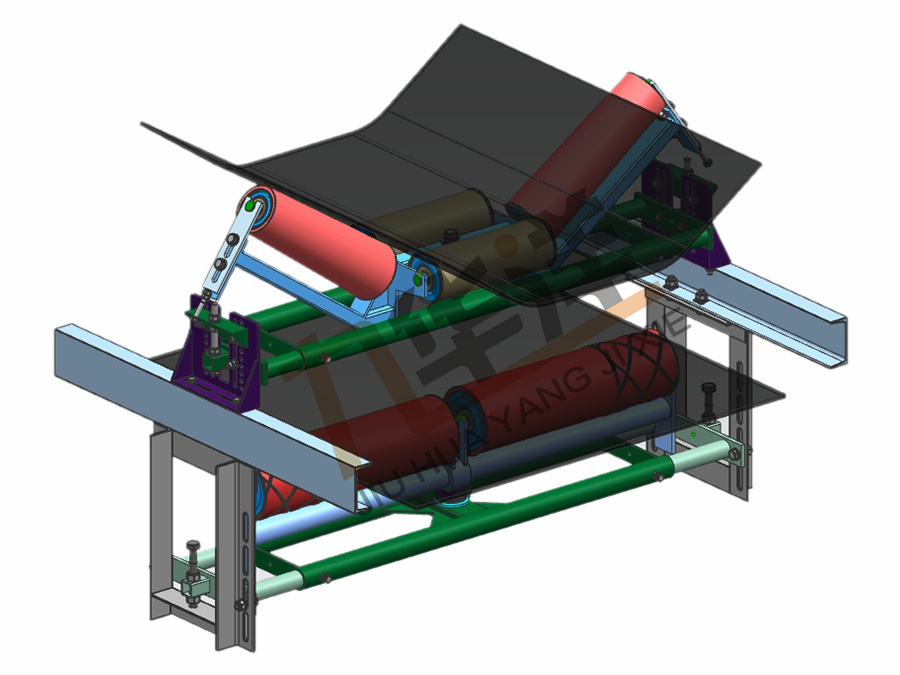

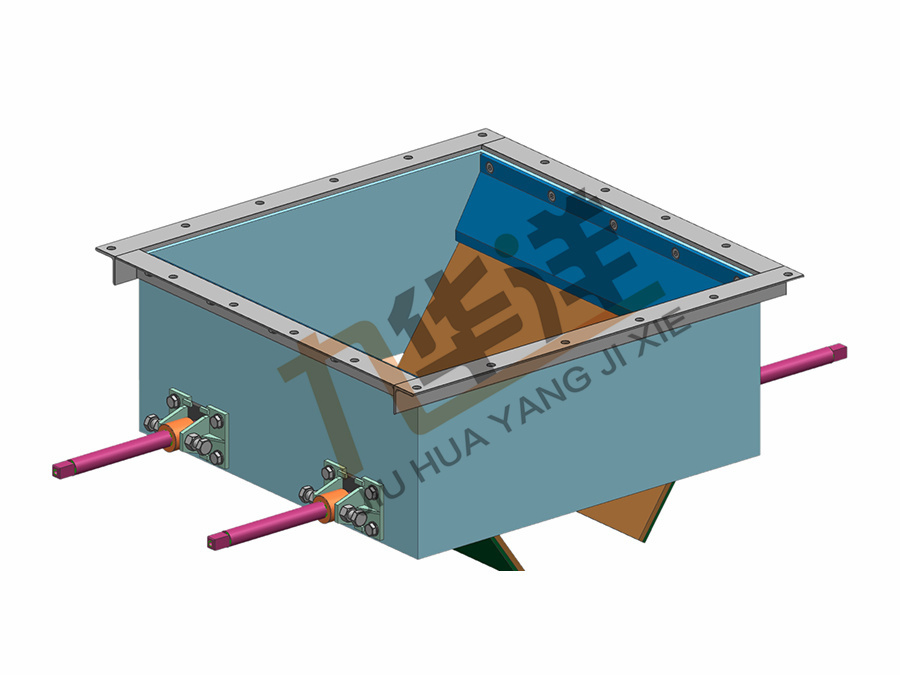

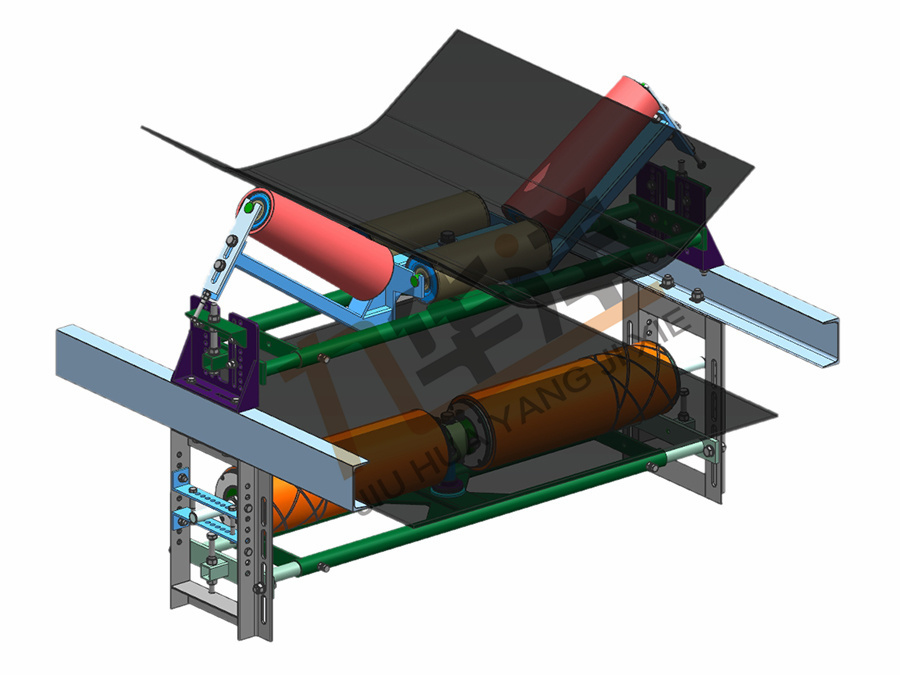

JHY maintenance-free corrector

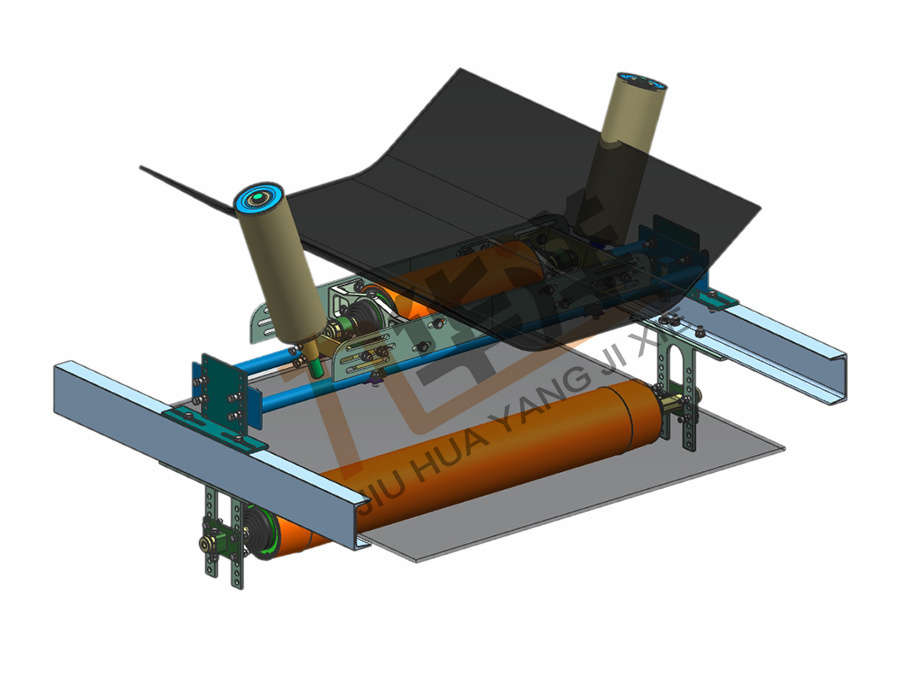

JHY maintenance-free corrector

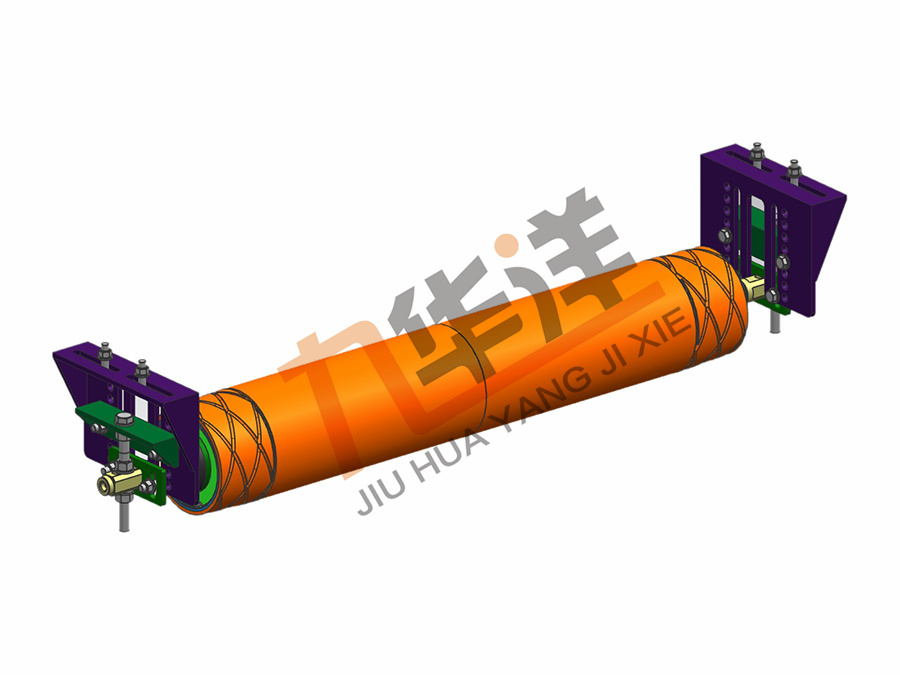

JHY maintenance-free corrector(Single-return flat type)

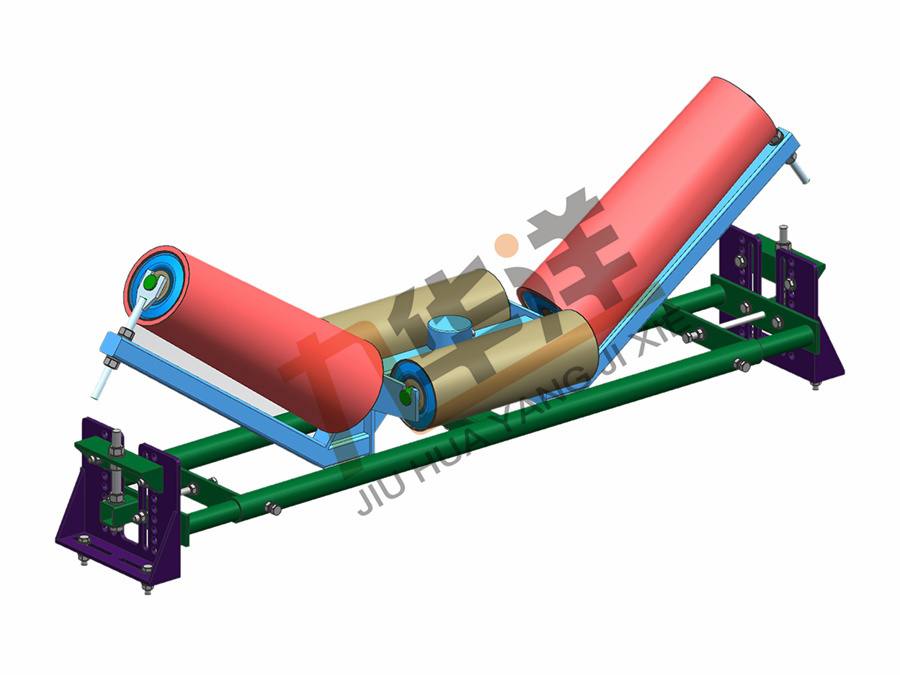

JHY maintenance-free corrector(Troughing type)

JHY maintenance-free corrector

JHY maintenance-free corrector(Double-return flat type)

Previous page

Previous page

Related Products

MESSAGE