Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

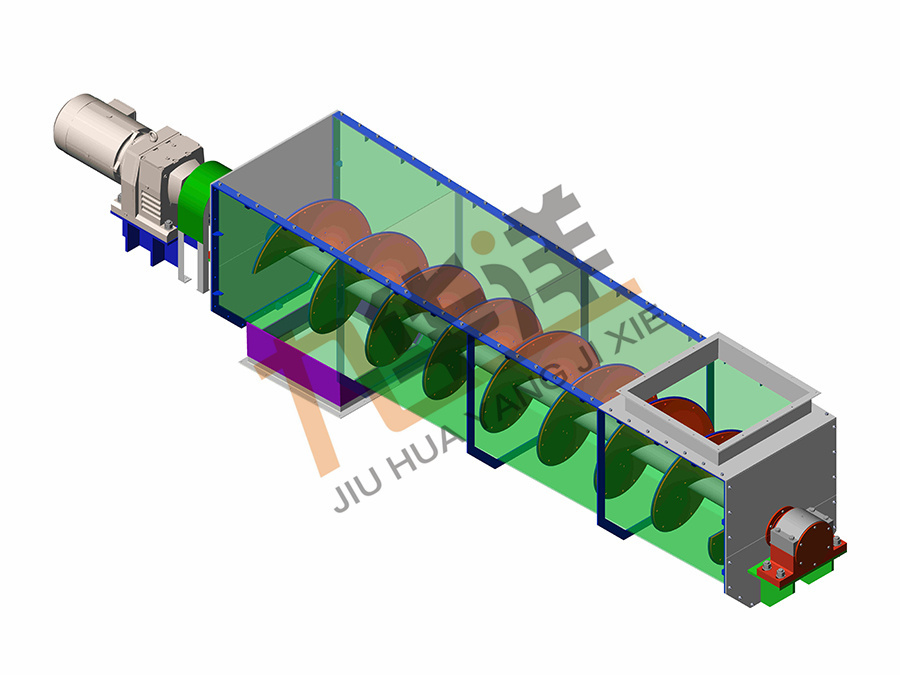

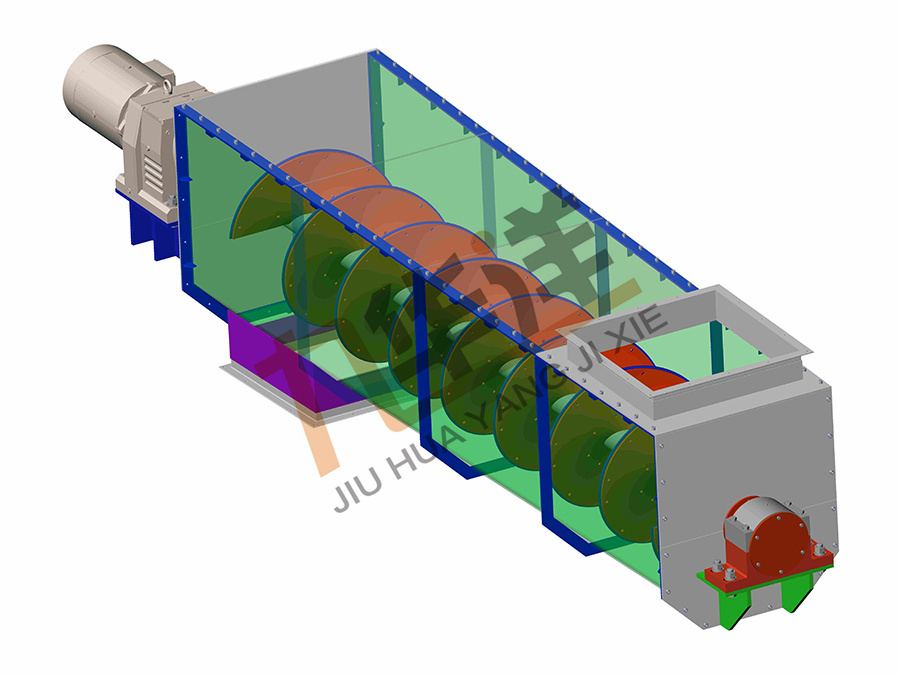

Screw anti-stuck feeder (no vibration, self-locking, stepless adjustment)

Screw anti-jamming feeder is mainly used for reliable continuous supply of various bulk materials. Drive motor frequency conversion speed regulation, to meet the load can be adjusted at any time, to ensure the accurate feeding flow; When working, uniform feeding, no jam, stable and reliable, fully meet the actual needs of various sites. When shut down can effectively self-lock, no slip, no jam. The equipment has many advantages, such as no vibration, low noise, completely closed, no dust, stable and reliable operation even if the sticky and wet material, easy maintenance and so on.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Working process

The equipment drives the reducer by the motor to drive the spiral spindle to rotate, and the material enters the working chamber of the equipment from the bin through the feeding port, and the rotating spiral blade evenly pushes the material to the discharging port and falls into the next level of equipment.

Main advantage

◎ Non-stuck and non-blocked shell optimization design is a streamlined and gradually expanded anti-stuck structure along the output direction of materials to prevent materials from getting stuck between the shell (fixed body) and spiral blade (moving body); the material flow channel (contact surface is equipped with wear-resistant lining plate) is streamlined, and the exit section is gradually enlarged relative to the entrance section to ensure that there is no jam.

The speed of spiral blade can be adjusted by motor frequency conversion to meet the adjustment requirements of response load output and ensure the accuracy of feed flow.

The stable and reliable motor drives the reducer to drive the spiral blade to rotate at a low speed. The feed is continuous and uniform, and the impact on the lower equipment is small. Simple and reliable structure.

◎ It can be used for wet material motor + reducer to drive the spiral blade to rotate and drive the material to move forward continuously with good fluidity; it can run stably and reliably even if the material is wet and sticky.

◎ It can be used for block mineral materials due to the large diameter of spiral blade, large pitch, relatively low speed, streamline design, mechanical and electrical protection devices are set; general conveying material particle size up to 300mm, even if the material with more debris can also be stable and reliable operation.

◎ Effective self-locking spiral structure in standby + reducer with automatic locking function when shutdown, no need to install special valves.

Helical blade adopts matrix + liner structure, easy to replace after wear and small maintenance.

◎ Safety and environmental protection screw anti-jamming feeder is fully closed, no dust overflow during the feeding operation of equipment; driven by motor, the spiral blade rotates evenly to feed, smooth operation, no vibration and no noise, low dynamic load requirements on the basic structure.

Structural composition

◎ The equipment is composed of variable frequency motor, reducer, elastic coupling, split bearing seat, streamlined shell, spiral conveying shaft, support seat and electric control box.

◎ Motor + reducer as the power source, the actual speed can be obtained by frequency conversion; drive spiral blade rotation to achieve continuous and uniform conveying of materials.

◎ The output of the screw anti-jamming feeder can reach 2000t/h, and the rotation speed of the screw blade can be adjusted by adjusting the frequency to meet the actual load needs.

Screw anti-stuck feeder

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO