Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

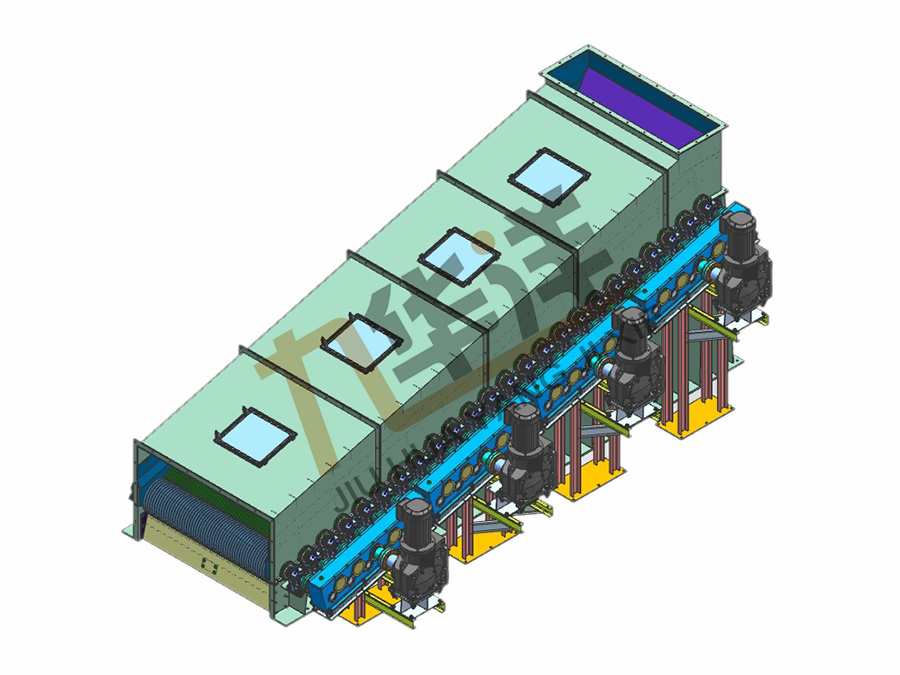

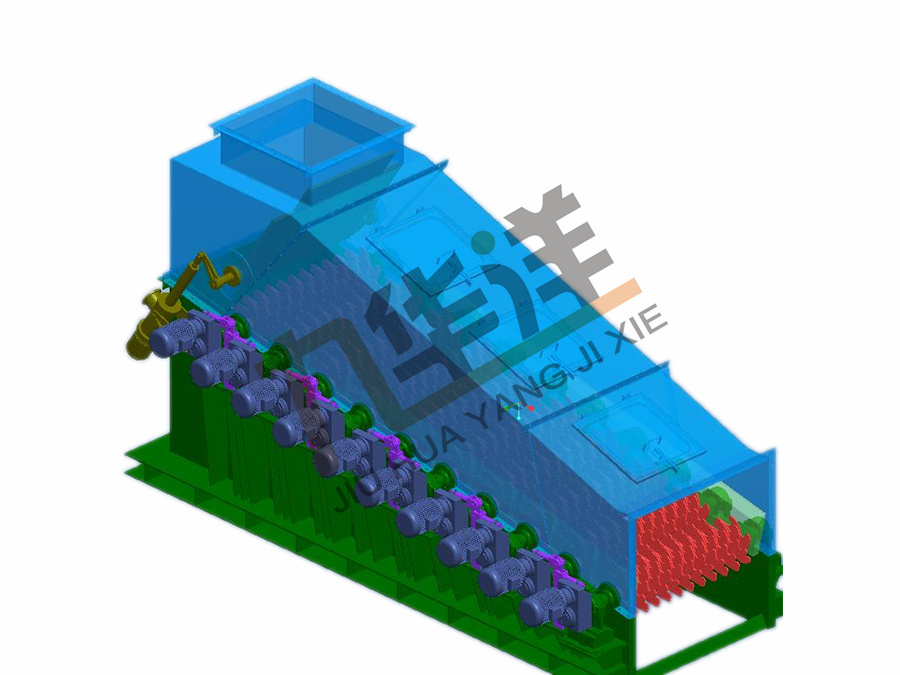

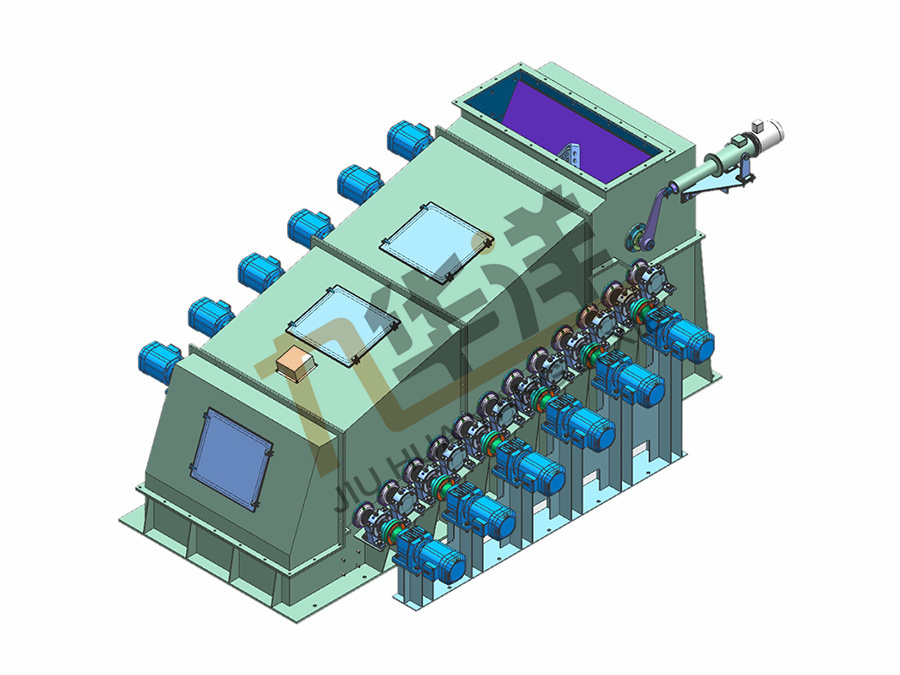

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

Wet and viscous material roll type fine screening machine(6-200mm)

Structure principle: It is composed of frame, shield, feed port, arc baffle, transmission device, sealing device, roller screen shaft, blanking port, etc. The efficiency of screening depends on the size of the area of the screen hole or slit.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Typical application

◎ In the circulating fluidized bed boiler power plant, the coal transport crusher shall be divided according to the particle size, and the fine material ≤10mm will not enter the crusher.

◎ Classification treatment between small materials and powder in coal preparation plant, fine materials ≤6mm will not be washed.

◎ Used in mining, coal, metallurgy, coking, chemical industry, non-ferrous metal, grain and other coarse and fine separation industries.

Technical characteristics

◎ Forced sinusoidal conveying, no plugging, screen surface conveying speed is greater than incoming speed.

◎ Roller screen shaft is not set a central shaft, filter screen shaft is provided with discharge device, no plugging.

◎ The area of the screen seam is much larger than the area of the screen surface, and the penetration rate is high.

◎ Can effectively screen slime and other sticky wet materials, will not stick.

◎ Special flexible sealing device, no exposure, no powder, low noise.

◎ wear-resistant material, maintenance free for 3 years of continuous operation.

◎ can be attached to the distributor, effectively improve the utilization rate of screen surface.

◎ Can be added to remove iron function, remove magnetic metal impurity.

◎ Can be started with load, can be interlinked with the system.

◎ The total power of the equipment is small and the energy consumption is low.

Common specification

|

Roll type fine screen machine |

Screening size(mm) |

Screen width(mm) |

Number of sieve shafts |

Rated output(t/h) |

remarks |

|

JHYGXS1006 |

6、8、10 |

1000 |

6 |

150-200 |

Affected by physical parameters such as material type, moisture content, viscosity, debris content, and particle size distribution range, technical parameters of equipment may change. |

|

JHYGXS1208 |

6、8、10 |

1200 |

8 |

300-400 |

|

|

JHYGXS1410 |

6、8、10 |

1400 |

10 |

500-600 |

|

|

JHYGXS1614 |

6、8、10 |

1600 |

14 |

800-900 |

|

|

JHYGXS1818 |

8、10 |

1800 |

18 |

1000-1100 |

|

|

JHYGXS2022 |

8、10 |

2000 |

22 |

1200-1300 |

|

|

JHYGXS2224 |

8、10 |

2200 |

24 |

1500-1600 |

Wet and viscous material roll type fine screening machine

Previous page

Previous page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO