Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

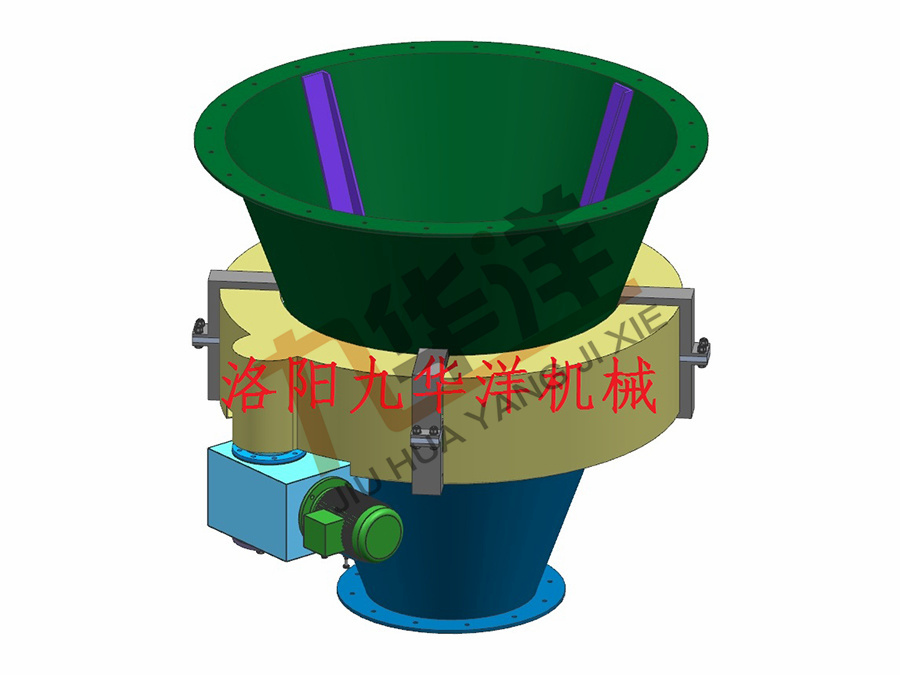

Rotary bin clogging removal machine (dredge machine)

Scope of application: inverted cone of steel rotary bin

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Structural principle

The rotary silo plugging cleaning machine is divided into three parts, the upper and lower parts are divided into static silo, and the middle part is the rotary plugging cleaning driving part. Its operating principle is: the reducer drives the main drive rotation, the scraper installed on the driven big tooth plate runs synchronously with it, scraping along the warehouse wall, the blocked coal from the coal bucket wall, so that it loses the supporting force point with the attached wall, so as to automatically fall under the action of its own gravity, clean up the blockage, keep the unimpeded coal bucket, fundamentally solve the problem of the original coal bunker blocking coal.

Technical parameter

◎ Installation position: block coal bunker section

◎ Connection form: flange, welding can be

◎ External dimension: The diameter is the user's existing coal bunker, and the height is not more than 2000mm according to the situation of coal plugging on site.

Characteristic performance

◎ Sealing features: automatic compensation type labyrinth seal, divided into upper and lower sealing. Pulverized coal is a poor medium, the general sealing is difficult to achieve, the new material used in this equipment has the advantages of reliable sealing, durable, adjustable.

◎ Structural features: The rotary scraper circularly scraping along the warehouse wall, so that the coal powder attached to the wall is separated from the warehouse wall, so that it loses the force point and falls off. Scraper and drive synchronous, flange connection, easy installation.

◎ Stable and reliable transmission: the mode of motor + reducer drive is adopted. The driving and transmission parts are arranged outside the warehouse wall, which will not hinder the flow of coal in the warehouse, and the transmission is stable and reliable.

◎ High degree of automation: PLC control, can realize the local and remote monitoring, can be set according to user needs manual, timing, automatic and other operation control mode, in addition, with automatic detection and start mode, when the equipment is broken off, to ensure the normal flow of coal.

◎ Long service life of the equipment: the blade of the component is made of alloy steel formed by the whole one-time forging, which has high wear resistance and strength and can effectively prevent the equipment from rust, fracture and wear, and has a long service life.

Scope of application

Inverted cone of steel rotary bin

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO