Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

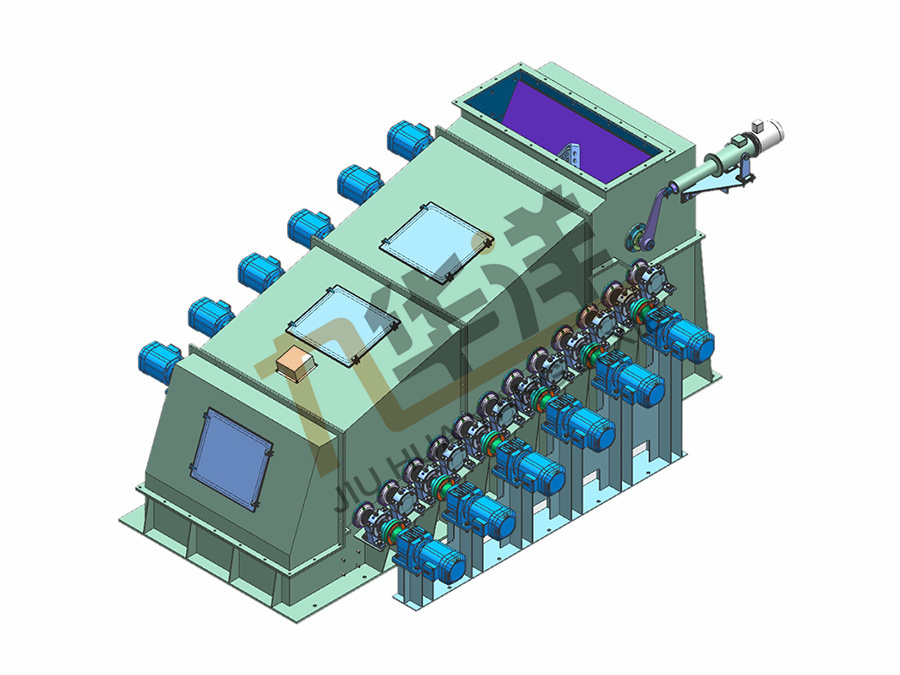

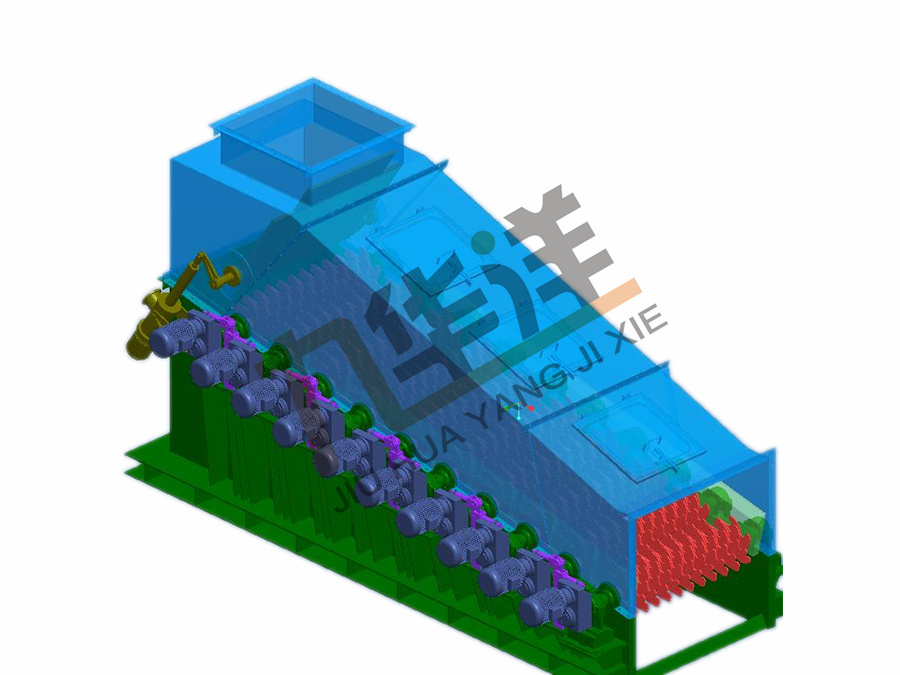

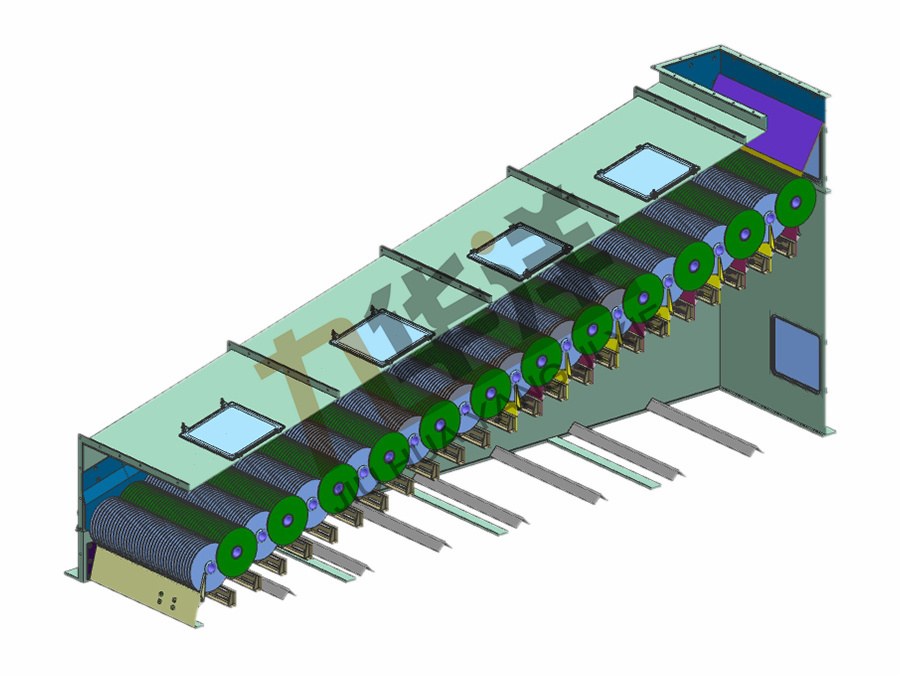

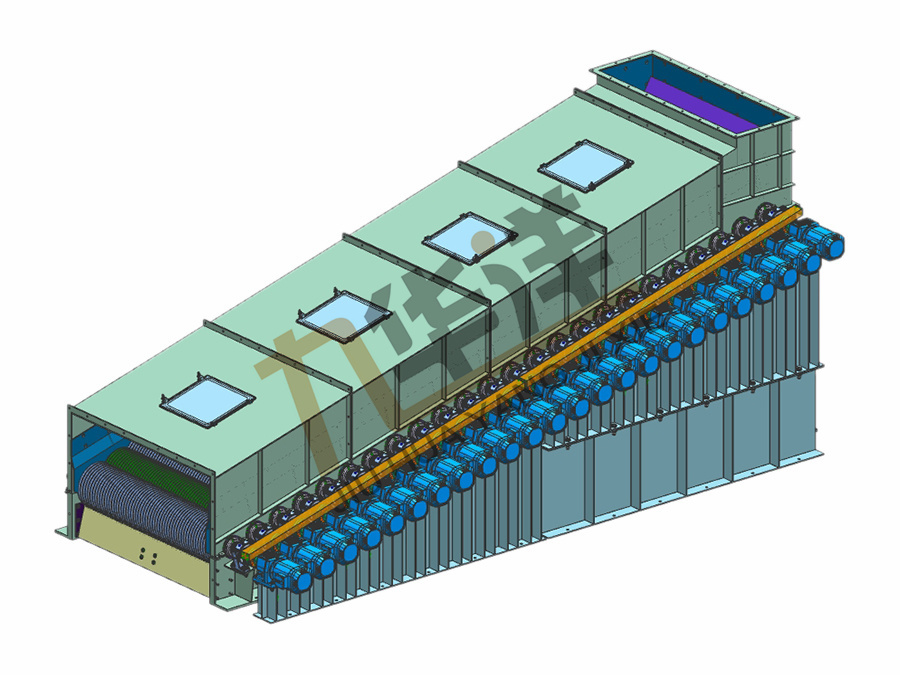

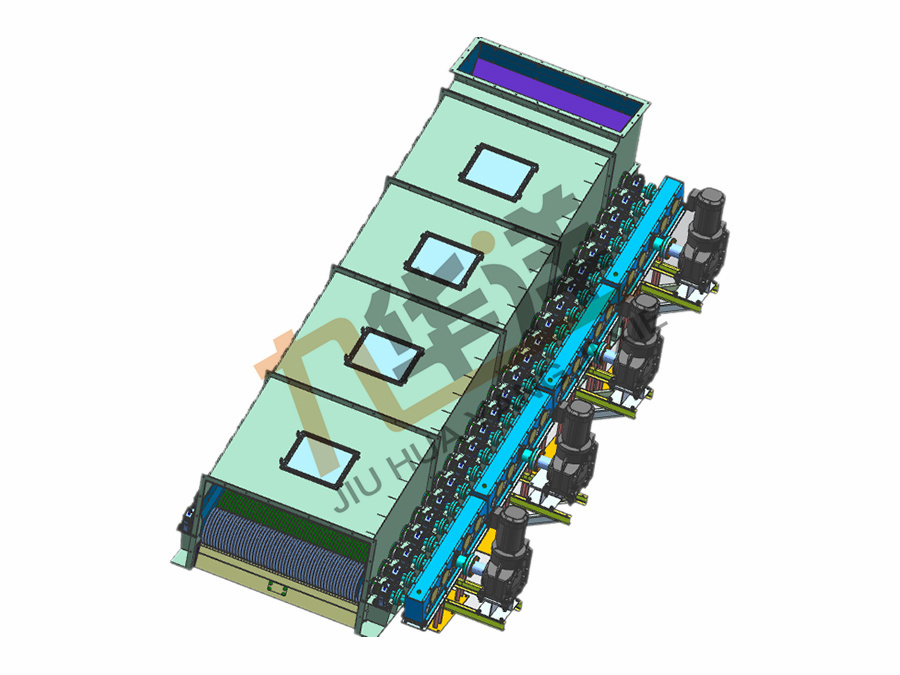

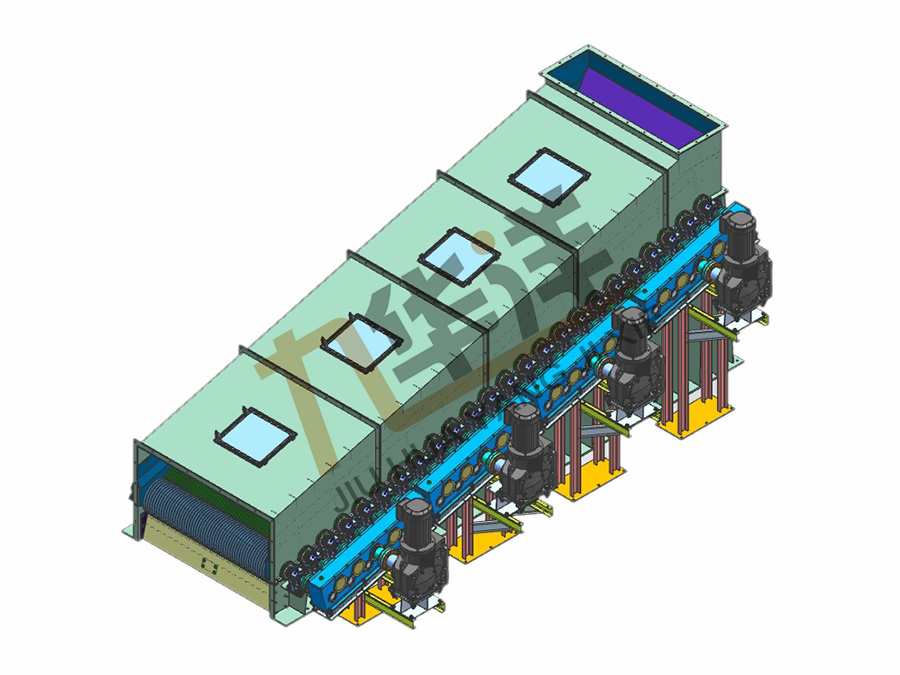

Wet material pan type fine screen machine(3-150mm)

Working principle: Loose is the premise of stratification, stratification is the completion of screening conditions, through screening is the purpose of screening; The screen axis rotates in the same direction, the screen pieces are cross arranged, and the motion direction between the adjacent cross screen pieces is opposite; Material flow by the sieve shaft power transmission at the same time is fully agitated, sinusoidal movement along the screen surface, less than the screen gap of the material by gravity, centrifugal force and friction force, is forced to separate the discharge, through the sieve seam to achieve screening. Each screen shaft is provided with a self-cleaning device, which can effectively scrape the attachments and winding objects on the screen shaft and screen piece, and maintain the opening rate of 100%. Open holes are installed on both sides of each box of the disc fine screen machine. If the material is blocked, the signal of the photoelectric switch is blocked by the material beyond the time set by PLC, and the electronic control system sends out the local sound and light alarm.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

Working principle

Loose is the premise of stratification, stratification is the condition to complete screening, screening through is the purpose of screening; The screen axis rotates in the same direction, the screen pieces are crossed, and the motion direction between the adjacent cross screen pieces is opposite.

◎ The material flow is fully stirred by the screen shaft power transmission at the same time, the sinusoidal movement along the screen surface, less than the screen gap of the material by gravity, centrifugal force and friction force, is forced to separate and discharge, through the screen seam to achieve screening.

◎ Each screen shaft is equipped with a self-cleaning device, which can effectively scrape the attachments and entanglements on the screen shaft and screen piece, and maintain the opening rate of 100%.

◎ Open holes on both sides of each box of the disc fine screen machine to install the photoelectric switch, the material blocking situation occurs, the photoelectric switch signal is blocked by the material beyond the time set by PLC, the electronic control system will send out the local sound and light alarm.

Field of application

◎ It relates to the separation technology of solid bulk materials or solid liquid interphase materials, especially for the dry screening of coal, minerals and any other difficult screening materials.

◎ The fine particle material can be bypassed, so as to save a lot of related equipment purchase cost and operation cost for users, and can greatly reduce the water consumption and energy consumption in the operation process.

◎ More sieve and less crushing is suitable for coal preparation for gasification and fluidized bed boiler power generation. The final coal ≤10mm is transported directly to the circulating fluidized bed boiler through the crusher and into the conveyor belt; > 10mm granularity into the fine crusher; Improve the operation efficiency of the crusher and reduce its unnecessary load.

◎ More screen and less washing is suitable for coal preparation plant, usually no longer washing pulverized coal ≤6mm (directly supply to power plant or other users), and > 6mm particle size coal is sent to jig for sorting or washing.

◎ Aggregate application, remove fine granular materials, sift and recycle materials.

◎ It is used for screening of wet or wet materials or dry materials, classifying materials with small particle size distribution, so that the powder ore and block ore can be separated effectively.

Typical application

◎ In the circulating fluidized bed boiler power plant, the coal transport crusher shall be divided according to the particle size, and the fine material ≤10mm will not enter the crusher.

◎ Classification treatment between small materials and powder in coal preparation plant, fine materials ≤6mm will not be washed.

◎ Coal by-pass pulverized coal and dry screening; Preconcentration process of coking coal.

◎ Ore washing workshop, more screening less crushing; Fine material no longer enters the high pressure roller mill or cone crusher, improving efficiency and output.

◎ Metallurgical industry raw material factory, powder ore and block ore separation.

Actual effect

◎ It is especially suitable for harsh working conditions such as large flow, strong viscosity and complex components without changing the original material properties.

◎ For the wet and sticky materials, the screening efficiency is more than 90%, the grading size is accurate, stable and reliable.

◎ In the process of material conveying, strip, block and other arbitrary geometric shape can be effectively separated.

◎ Each screen shaft is equipped with a self-cleaning device to scrape away the attachments and entanglements on the screen shaft and screen piece.

Technical characteristics

◎ The material moves sinusoidal along the screen surface, continuously rolling stratification, prolonging the contact time and increasing the chance of penetrating the screen.

◎ Dynamic screen, no plugging, high opening rate, material through screening efficiency up to 90%.

◎ Self-cleaning, non-stick material, non-winding, sundries through strong, strong adaptability to materials.

◎ Special flexible sealing device, no exposure, no powder, low noise.

◎ The screen is made of wear-resistant material, which is maintenance-free in continuous operation for 3 years.

◎ can be attached to the distributor, effectively improve the utilization rate of screen surface.

◎ Can be added to remove iron function, remove magnetic metal impurity.

◎ Can be started with load, can be interlinked with the system.

◎ The total power of the equipment is small and the energy consumption is low.

Common specification

|

Disc type fine screen machine |

Screening size(mm) |

Screen width(mm) |

Number of sieve shafts |

Rated output(t/h) |

remarks |

|

JHYPXS1206 |

3、6、8、10 |

1200 |

6 |

100-150 |

Affected by physical parameters such as material type, moisture content, viscosity, debris content, and particle size distribution range, technical parameters of equipment may change. |

|

JHYPXS1208 |

3、6、8、10 |

1200 |

8 |

200-250 |

|

|

JHYPXS1610 |

3、6、8、10 |

1600 |

10 |

300-350 |

|

|

JHYPXS1614 |

6、8、10 |

1600 |

14 |

500-550 |

|

|

JHYPXS2018 |

6、8、10 |

2000 |

18 |

800-880 |

|

|

JHYPXS2022 |

6、8、10 |

2000 |

22 |

1000-1100 |

|

|

JHYPXS2422 |

8、10 |

2400 |

22 |

1200-1300 |

|

|

JHYPXS2426 |

8、10 |

2400 |

26 |

1500-1600 |

Wet and viscous material disc type fine screen machine

Previous page

Previous page

Related Products

MESSAGE