Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

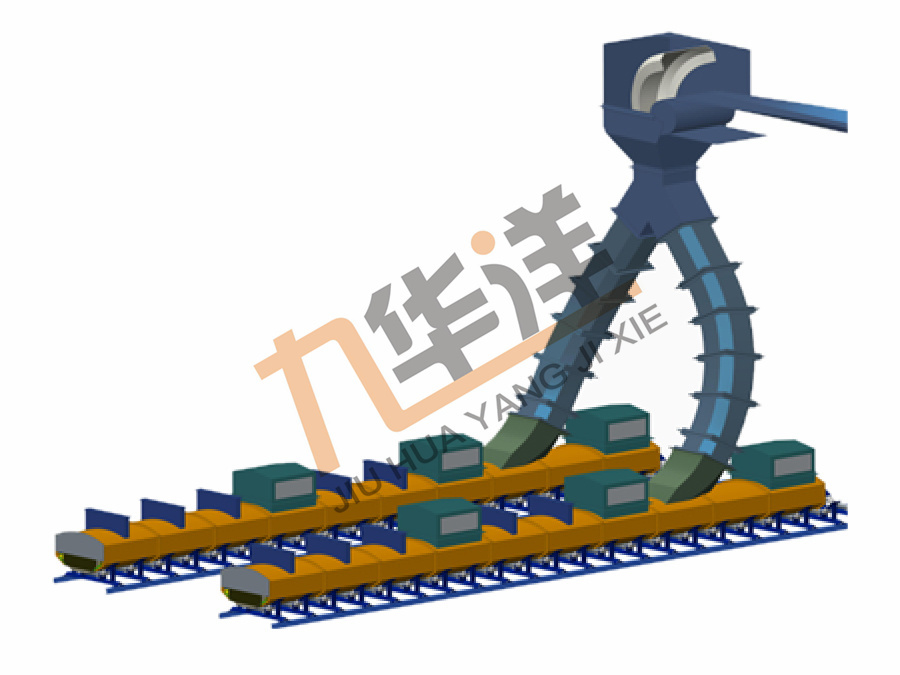

Curved anti-blocking dust suppression blanking pipe

Corresponding advantages: The curve blocking blanking pipe system adopts streamline optimized section design, which can collect materials well, slow down the falling speed of materials, ensure the blanking point to the center, avoid blocking, scattering and other phenomena. Curve chute system design not only well avoid chute clogging, belt off-load running problems, but also for dust control has played a good effect, equipment operation is more stable, reliable, safe, economic.

Keywords: Jiuhuayang Mechanical Equipment

Category:

DESCRIPTION

Have a problem

The traditional bulk material transfer system can not meet the modernization requirements of large volume and high speed belt conveying system. Dust pollution, chute blockage, belt deviation, serious scattering, equipment wear and so on have become prominent problems in the whole conveying system.

Solve the problem

◎ The belt head is installed with the head curve hopper diversion device according to the material throwing track design, which can avoid the plugging phenomenon of funnel, restrain the induced wind and reduce dust;

◎ The original positive tee structure is changed into a streamlined ship-type electric tee or a streamlined pendulum cylinder electric tee, which can not only ensure the convenient switching of the tee, but also prevent the leakage of the tee. The baffle at different stations can ensure that the falling material impact Angle is not more than 30 degrees, and the bottom outlet of the tee is designed to match the chute U-shaped structure.

◎ The blanking pipe adopts curvilinear chute structure, smooth transition, to ensure the controlled flow of materials, avoid the phenomenon of chute accumulation, and can effectively suppress dust. The design of the whole system is based on the linear structure (including the belt head curve hopper diversion device, streamline electric ship type tee/swing cylinder tee, the middle section of U-shaped section/multilateral body/circular structure and other streamlined coal falling pipe, the lower feeding spoon) to effectively control the speed and direction of the material flow, without the need for buffer air lock, to prevent impact dust and material blocking.

Corresponding advantage

Curvilinear anti-blocking blanking pipe system adopts streamlined optimized section design, which can collect materials well, slow down the falling speed of materials, ensure that the blanking point is centered, and avoid the phenomenon of blocking and scattering. Curve chute system design not only well avoid chute clogging, belt off-load running problems, but also for dust control has played a good effect, equipment operation is more stable, reliable, safe, economic.

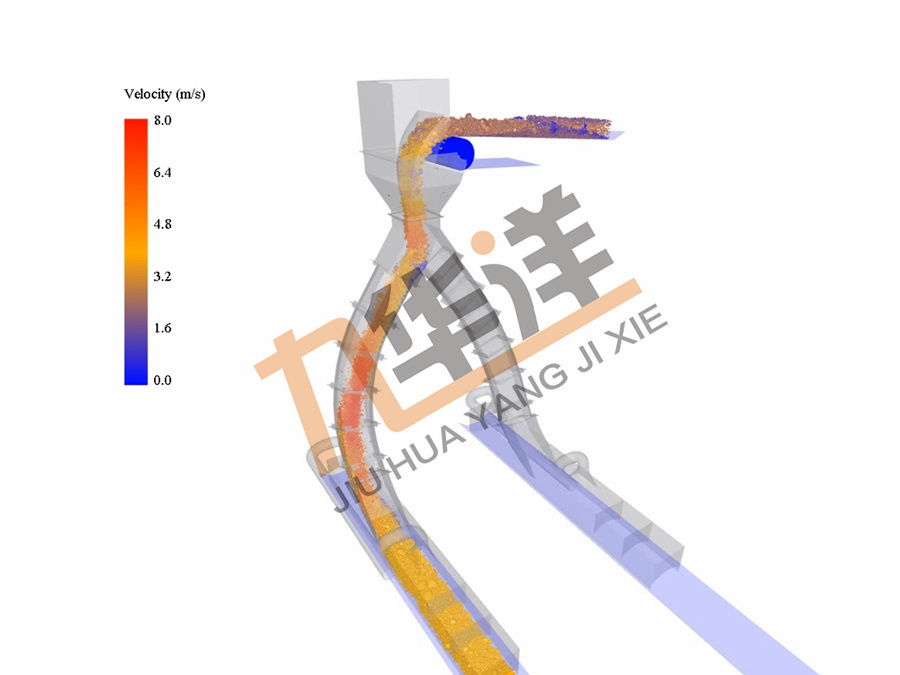

Design principle

EDEM technology is adopted to streamline the coal falling pipe, which reduces the Angle and the coal blocking and dust blowing caused by the impact of materials. Based on the discrete element method, the curve anti-blocking blanking pipe technology adopts UG NX design and modeling, with the help of EDEM granular science simulation software, the mechanical model is established according to the physical parameters of the material (elastic modulus, water content, ash content and particle size distribution range), and the actual data of the dynamic Angle of rerest of the material is coupled through EDEM. Determine the elasticity, viscosity, plasticity, deformation grade, sliding, expansion and fluidity of the material particles, and finally determine the simulation parameters; The motion characteristics of particle system in the process of conveying bulk materials are simulated to assist designers in designing, testing and optimizing the equipment for handling bulk materials. The belt head is designed with a curved hopper diversion device to make the material flow gradually contact with the baffle at a small impact Angle (theoretical entry Angle is less than 30°), so as to reduce the impact of the material flow on the baffle; The body of the curve blocking blanking pipe adopts a streamlined structure, and the section shape is mostly "U" shape or circular section or polygon structure. The outlet adopts the spoon structure of forward expansion and variable section, and deep inside the material guide groove, 200 ~ 300mm from the bottom of the belt, so that the speed of the material flowing into the next level of the belt and the speed of the belt conveyor. By collecting materials, the curve chute realizes the controllability of irregular loose materials, so as to prevent chute clogging, reduce impact, inhibit induced wind, reduce dust concentration and other purposes.

Design basis

◎ Combined with different transfer station layout forms, carry out targeted optimization design.

◎ Ensure that the impact Angle of the material and any part of the chute is not more than 30 degrees.

◎ The flow of materials can be guaranteed by optimizing the radian and section shape of the chute.

◎ Through the change of chute section and the change of material direction, the formation of induced wind is inhibited and the dust is reduced.

◎ Ensure that the material cannot directly vertically impact on the next level of belt, and ensure that the material must slide into the belt through the chute.

◎ Ensure the same speed of materials, left and right alignment into the next level of belt, minimize the impact of materials on the belt.

Implementation plan

Simulation material flow is adopted to simulate the actual working condition. The application of EDEM dispersed material flow technology makes the material flow regularity in the streamlined coal falling pipe, controls the velocity and flow direction of materials, avoids the dust generated by the collision between materials, ensures the absolute alignment of the material received by the belt, and avoids the deviation caused by the uneven material received by the belt. Reduce the impact of damage to equipment, reduce noise, avoid material blocking, inhibit the generation of dust; The buffer air lock is cancelled and the structure of coal falling pipe is optimized.

Head curve hopper diversion device: the hopper diversion device is installed in the head funnel, can make the material flow from the parabola direction with a small impact Angle (theoretical entry Angle is less than 30°) and diversion device gradually enter, so that the material flow in accordance with the expected set flow path into the chute, control the direction of materials; The hopper diversion device can meet the requirements of different bandwidths, different speeds and different sizes of the head roller. It is installed by adjustable suspension base and adjusted by the screw adjusting mechanism with spring shock absorption to adjust the position and control the direction of materials.

Curve anti-blocking blanking pipe: through the change of conveying pipe section, smooth transition to ensure the material collection so as to avoid chute accumulation blockage, and can inhibit the formation of induced wind to reduce the generation of dust; The curved chute is designed with streamlined section, multilateral body or circular structure. Export type or fish sac type feeding spoon, to ensure the same speed of materials, left and right to enter the next level of belt, reduce the impact of materials on the belt, material guide groove and overflow apron.

Middle curve buffer diversion device: high wear resistance, impact resistance, with good elasticity of polyurethane elastomer. To meet the needs of different shapes of chute structure, ensure the collection and transportation of materials, cut off the flow of materials when the shear air generated by the induced wind, inhibit the generation of secondary dust; The device adopts withdrawable design for easy installation, maintenance and replacement.

Streamline electric boat tee: easy to switch at the same time can prevent the leakage of three, in different stations can ensure that the baffle with the flow diversion device falling material impact Angle is not more than 30 degrees; The bottom outlet of the electric anti-stuck tee is designed to be U-shaped structure with the same size as the chute.

Streamline electric swing cylinder tee: swing cylinder tee (or four) is a transfer mechanism that can realize accurate shunt function, no jamming, easy to switch; The impact Angle of the falling material of the collection and diversion device is not more than 30 degrees. The bottom outlet of the dynamic swing cylinder is designed to be U-shaped structure with the same size as the chute.

Performance comparison

Comparison table of effect between curved coal falling pipe and traditional coal falling pipe

|

NO. |

Contrast item |

Traditional blanking pipe |

Curved anti-blocking blanking pipe |

|

1 |

Design standard |

Principle of material abrasives |

Controllable, clustered and orderly |

|

2 |

Head funnel |

The impact is large and the dust is serious |

No impact and dust generation |

|

3 |

Material velocity |

irregularity |

Regular non-extrusion |

|

4 |

Coal falling pipe structure |

Square, many corners, many dead corners |

The linear shape has no dead corners |

|

5 |

clogging |

It is easy to get clogged at corners |

non-clogging |

|

6 |

Lining plate |

Large area and small effective utilization area |

Small area and high utilization area |

|

7 |

Buffer air lock |

Must be configured and high maintenance cost |

No configuration required |

|

8 |

System dust phenomenon |

Very serious |

Less dust |

|

9 |

Investment in dust removal equipment |

Large investment |

Small investment |

|

10 |

Operating ambient noise |

Loud noise |

Low ambient noise |

|

11 |

Trestle flush |

Frequent flushing, waste of water, high cost |

Few washing times, energy saving and emission reduction |

|

12 |

To the guide groove |

Severe impact and wear, frequent replacement |

No impact wear and maintenance free |

|

13 |

Damage to rollers |

Severe damage |

Minimal destructive power, beyond the service life |

|

14 |

Tape deviation phenomenon |

Bad receiving point induces deviation |

The material is good to the center, not easy to run off |

|

15 |

Field working environment |

Big dust, loud noise, bad environment |

No dust, low noise, good environment |

|

16 |

Safety hazard |

Easy to cause electrical equipment damage |

Security risks are greatly reduced |

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE