Welcome to the official website of Luoyang Jiuhuayang Machinery Equipment Co., Ltd!

Tel:+86-379-65112008 Email:jiuhuayang999@163.com

-

-

Intelligent unmanned belt conveying

-

JHY maintenance-free corrector

-

JHY intelligent correction system

-

Material flow correction and alignment device

-

Spoke-type waist-drum-shaped slag-discharge roller

-

Torsion correction device of tubular belt conveyor

-

Tape longitudinal tear protection device

显示更多 -

-

Automatic belt cleaning device

-

Tape washing, cleaning and air-drying device

-

Combined tape cleaning device

-

Tape aerodynamic slag cleaner

-

Tape bath cleaning and air-drying device

显示更多 -

-

Impurity and block removal of bulk materials

显示更多 -

Special screening equipment for bulk materials

-

Wet and viscous material disc type fine screen machine

-

Wet and viscous material roll type fine screening machine

-

Floating blocking roller screen

显示更多 -

-

Bulk material feeding equipment

显示更多 -

Block prevention and clearance of bulk silo

-

Controlled air pressure type clog-removing machine

-

Floating hyperbolic type clog cleaner

-

Rotary bin clogging cleaner

显示更多 -

-

Bulk material blocking and dust removal

显示更多 -

Bulk material handling device

-

Cleaner: polyurethane, carbide, brush cleaner

-

Buffering machine

-

Anti - card tee: boat type, pendulum type, baffle type

-

Plough type unloader

-

Air lock

显示更多 -

-

Bulk crushing and mixing in stages

显示更多 -

Bulk conveying unmanned operating system

-

Belt machine JHY intelligent correction system

-

Automatic belt cleaning device

-

Tape longitudinal tear protection device

-

Excessive bulk and debris removal

-

Transfer station comprehensive treatment system/blocking, dust removal

显示更多 -

-

-

-

Intelligent unmanned belt conveying

-

Automatic belt cleaning device

-

Impurity and block removal of bulk materials

-

Special screening equipment for bulk materials

-

Bulk material feeding equipment

-

Block prevention and clearance of bulk silo

-

Bulk material blocking and dust removal

-

Bulk material handling device

-

Bulk crushing and mixing in stages

-

Bulk conveying unmanned operating system

-

Intelligent dry separation system for coal and gangue(50~300mm)

JHY-X intelligent dry separator is a new equipment for gangue separation developed by Zaozhuang Xinyuanda Guowei Mechanical and Electrical Technology Co., LTD. The system is mainly composed of vibration distributor, belt conveyor, X-ray recognition instrument, high pressure air separation device controlled by high frequency and large flow solenoid valve, dust removal system, etc. It has been issued with explosion-proof certificate and radiation safety license for the production and sales of X-ray devices. Have raw coal system production conditions.

Keywords: Jiuhuayang Mechanical Equipment

DESCRIPTION

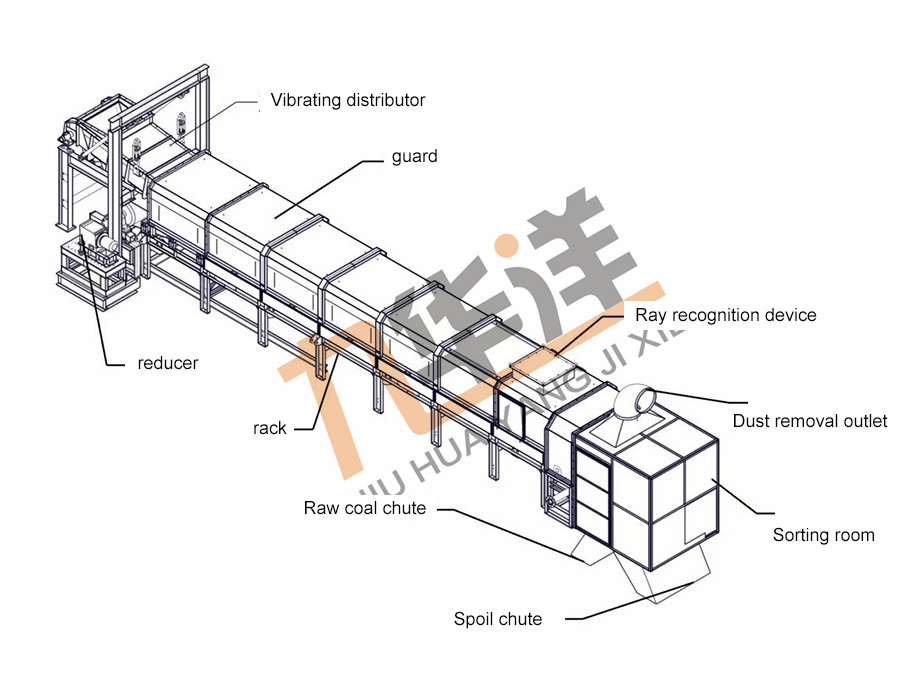

Introduction of JHY-X series intelligent coal gangue separation system

JHY-X intelligent dry separator is a new equipment for gangue separation developed by Zaozhuang Xinyuanda Guowei Mechanical and Electrical Technology Co., LTD. The system is mainly composed of vibration distributor, belt conveyor, X-ray recognition instrument, high pressure air separation device controlled by high frequency and large flow solenoid valve, dust removal system, etc. It has been issued with explosion-proof certificate and radiation safety license for the production and sales of X-ray devices. Have raw coal system production conditions.

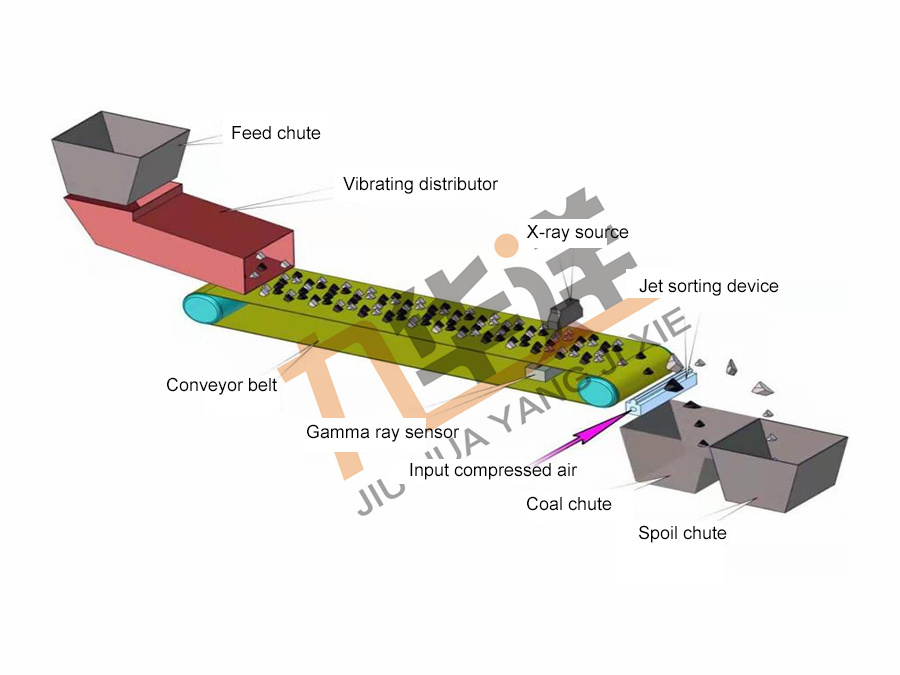

Sorting principle

The separation principle is that coal gangue and gangue are separated by using X-ray imaging recognition technology to obtain the location and related information of coal and gangue, and form different images according to the density difference of different minerals. Then artificial intelligence is used to process the obtained data, so as to realize the identification of gangue and lump coal. The identified materials are separated from gangue and gangue by controlling high-pressure air injection device. The following is a schematic diagram of sorting principle.

Main advantages of the system

(1) Wide sorting grain size, the granularity of 50 ~ 300mm for one-time sorting.

(2) The separation does not use water, reducing the amount of slime generation.

(3) High degree of intelligence, unattended, remote diagnosis.

(4) The system is simple, occupies small space, less equipment.

(5) Low operation cost, the cost of dry coal preparation is about 2 yuan /t.

(6) Large processing capacity, hourly processing capacity of 110-280t/h.

Equipment design and processing capacity

JHY-X series 50-300mm smart dry separator for coal gangue selection table

|

Technical parameter |

JHY12-50/300 |

JHY14-50/300 |

JHY20-50/300 |

JHY24-50/300 |

JHY28-50/300 |

|

Cloth belt width |

1200mm |

1400mm |

2000mm |

2400mm |

2800mm |

|

Processing capacity |

110-130t/h |

120-150t/h |

180-210t/h |

220-240t/h |

260-280t/h |

|

Theory matching ore type |

1.5-2.0Mt/a |

2.0-2.5Mt/a |

2.5-3.0Mt/a |

3.0-4.0Mt/a |

4.0-5.0Mt/a |

Factory test equipment

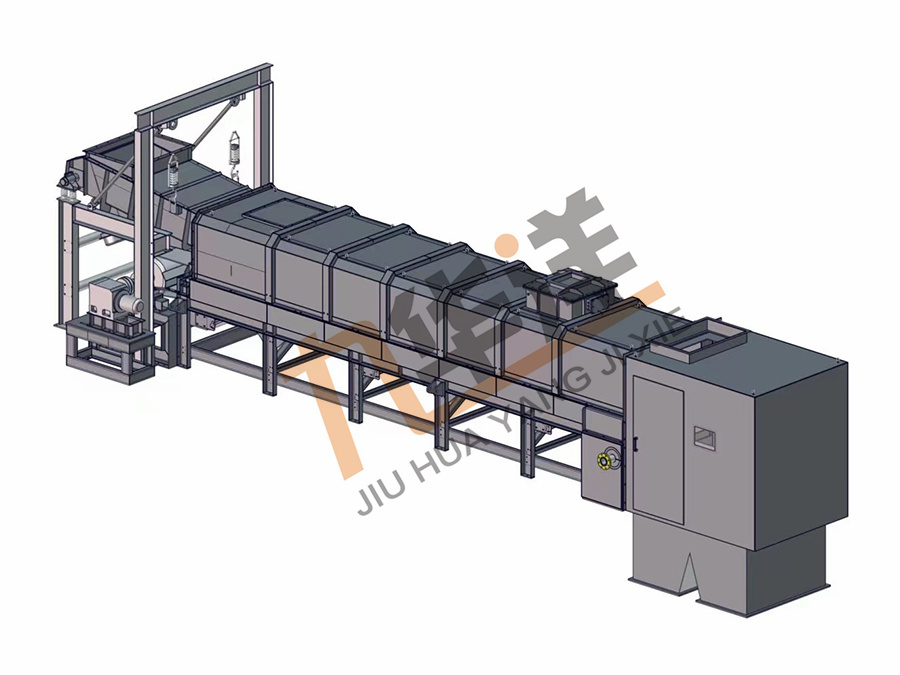

The experimental equipment can be used to test the samples in advance. First, the selectibility of coal can be preliminarily observed and the sorting effect can be visually viewed. The second is to set and optimize the sorting parameters of the sample in advance, so that it can reach production quickly after putting into production. The following is the factory test equipment diagram and test results display diagram.

Factory test prototype drawing

The result of dry separation test of sample

Suggestions for intelligent dry selection

At present, the power plant needs to separate materials, about 100t per hour, particle size of 60-200mm, choose 1.2 meters wide JHY-X dry separator can realize all separation, into coal and block gangue two products.

JHY-X1.2 system main equipment selection and configuration table

|

Serial number |

Key words |

New/old |

Equipment name |

Model specifications and main technical parameters |

unit |

quantity |

|

Coal separation system |

||||||

|

1 |

Dry separator |

add |

Intelligent dry separator |

JHY-X1.2-300 dry separator, B=1200mm processing size 50-300mm |

Set of |

1 |

|

2 |

Dry separator |

Among them |

Mechanical structure of intelligent dry separator |

Set of |

1 |

|

|

3 |

Intelligent dry separator electric control system |

Set of |

1 |

|||

|

Intelligent dry separator platform software |

V1.0 |

Set of |

1 |

|||

|

Air supply system |

||||||

|

1 |

Air compressor |

add |

Air compressor |

Q=24m³/min,0.85MpaN=132kw |

tower |

1 |

|

2 |

air receiver |

add |

air receiver |

V=4m3,V=8m3P=0.8Mpa |

个 |

1 |

|

3 |

dryer |

add |

Cold dryer |

N=5kw |

tower |

1 |

|

4 |

Precision filter |

add |

tertiary |

Set of |

1 |

|

|

Dust removal system |

||||||

|

4 |

Dust removal machine |

add |

Wet dust removal machine |

Q=1800M3/h,N=18.5kw |

Set of |

1 |

Main technology and sorting index

Sorting size:60-200mm

The gangue sorting rate is greater than 95%, and the coal lost in gangue is less than 2%

Previous page

Next page

Previous page

Next page

Related Products

MESSAGE

Luoyang Jiuhuayang Machinery Equipment Co., Ltd

Tel:+86-379-65112008

Fax:+86-379-69860218

Phone:+86-13525919832 +86-18625423423

Mobile website:www.jiuhuayang.cn

Email:jiuhuayang999@163.com

Add:Jianxi District, Luoyang City, Henan Province

Follow Us

Follow Us

© 2023 Luoyang Jiuhuayang Machinery Equipment Co., Ltd Powered by www.300.cn This website supports IPV6 SEO